Product Description

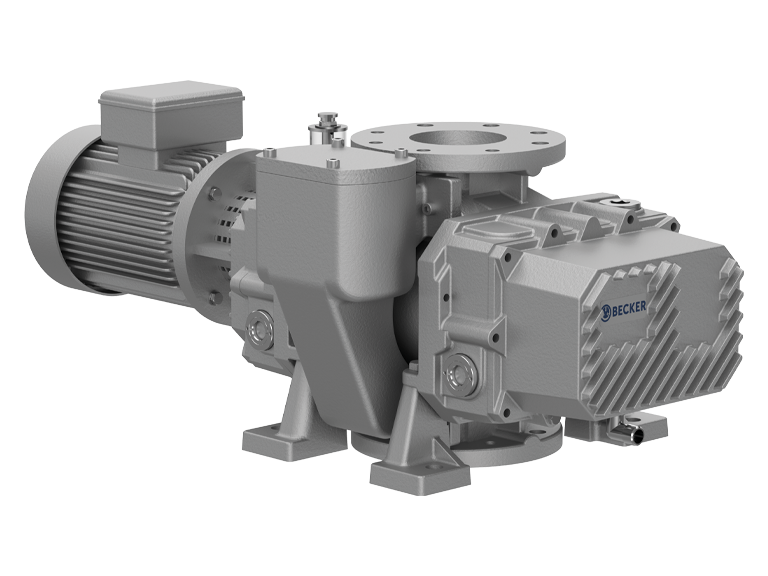

Energy Saving Industrial Roots Pump Low Pressure Mechanical Roots Vacuum Pump

Product Description

Product Parameters

|

Model |

ZJ-30 |

ZJ-70 |

ZJ-150 |

ZJ-300 |

ZJ-600 |

ZJ-1200 |

ZJ-2500 |

ZJ-5000 |

|

Ultimate total pressure(Pa) |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

|

Motor Power(Kw) |

0.75 |

1.5 |

3 |

4 |

7.5 |

11 |

22 |

45 |

|

Nominal Motor speed(rpm) |

2850 |

2850 |

2870 |

1450 |

2900 |

1400 |

2880 |

1450 |

|

Nominal Motor current(A) |

1.8 |

3.4 |

6.2 |

15.4 |

14.8 |

22.3 |

41 |

84.7 |

|

Pumping size(mm) |

650X315X255 |

770X315X255 |

1060X462X380 |

1330X556X505 |

1410X556X505 |

1710X1070X850 |

1820X1070X850 |

2700X1200X1100 |

|

Weight (with oil filling)kg |

76 |

96 |

200 |

502 |

520 |

1550 |

1620 |

4000 |

|

Type of protection(IP) |

55 |

55 |

55 |

55 |

55 |

55 |

55 |

55 |

Detailed Photos

Roots vacuum pump (abbreviated as Roots pump) is a rotary variable capacity vacuum pump without internal compression. It utilizes 2 8-shaped rotors to rotate in the pump casing to generate suction and exhaust effects. Its principle is similar to that of a Roots blower. Due to its operation in a low pressure range, the gas molecules have a large free range, and the resistance of gas leakage through small slits is high, so it can achieve a high compression ratio and can be used as a booster vacuum pump; But it cannot directly discharge the gas into the atmosphere alone, and needs to be used in series with the front stage vacuum pump. The extracted gas is carried into the atmosphere through the front stage vacuum pump.

Roots pumps are widely used in vacuum degassing, vacuum melting, vacuum treatment of molten steel in the vacuum metallurgy industry, as well as in devices such as space simulation and low-density wind tunnels to extract corrosive gases. It can also be used in production processes such as distillation, evaporation, and drying in industries such as chemical, food, pharmaceutical, and motor manufacturing.

The ZJ series Roots vacuum pump is a rotary variable capacity vacuum pump that requires a front stage pump to be used. It has a large pumping speed in a wide pressure range in China and is not sensitive to dust and water vapor in the extracted gas. It is widely used in industries such as metallurgy, chemical industry, food, and electronic coating.

Company Profile

HangZhou Sifang Vacuum Equipment Co., Ltd. specializes in the production of vacuum furnaces, vacuum pumps, steel drums and other products.”Sifang” is the registered trademark of the company’s products.

our company is 1 professional vacuum equipment manufacturer in HangZhou, China. We specialize in vacuum pumps, furnaces, systems and components for diverse applications. We produce rotary vane vacuum pumps, water ring vacuum pumps, reciprocating vacuum pumps, roots vacuum pump units, vacuum heat treatment furnaces, vacuum aluminum brazing furnaces, high temperature brazing fur- naces, vacuum sintering furnaces, monocrystalline silicon furnaces and other products. All these vacuum equipment are widely used in aviation, aerospace, military, railway, automobile, machinery, mold, electronics, metallurgy, scientific research and other fields.

We have professional engineer support, high efficiency sales team and competitive price superiority, and attract customers from all over the world, we export to over 40 countries, including Europe, Poland, Serbia, Turkey, Russia, USA, Mexico, Brazil, India, Thailand, Middle east and South Africa.

After several years’ development, We have achieved great progress, we are equipped with the AutomaticCNCmachines and multi-func- tion testing machines. Our R&D department provide the strong tech- nical support and enable us to receive some 0 E M, O D M projects. We can produce at least 3000 sets vacuum equipment per year. With our innovative and energy-efficient vacuum equipment that is put to work in a multitude of manufacturing and process applica- tions, we also offer you a comprehensive suite of CHINAMFG ser- vices to complement our products.

FAQ

1.Q: Are you a factory or trading company?

A: We are a factory and we have professional team of workers,Designers and inspectors.

2.Q:Do you accept custom?

A:Of course.We have professional teams who make your designs,photos,imagines and OEM orders into real production.

3.Q:What’s your advantages?

A: Quick response to your enquiry,

High quality control,

Reasonable price,

Timely delivery,

Excellent after-sales service,

OEM/ODM are welcome

4.Q:What’s your shipping terms?

A:If you need to ship by air,we can use DHL,UPS,FedEx,TNT or EMS.If you need to ship by sea,we have many good forwarders to work with,they can provide the best price for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Support |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil |

| Structure: | Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | Vacuum |

| Customization: |

Available

|

|

|---|

Can Roots Vacuum Pumps Be Used for Vacuum Impregnation in Manufacturing?

Yes, Roots vacuum pumps can be used for vacuum impregnation in manufacturing. Here’s a detailed explanation:

1. Vacuum Impregnation in Manufacturing: Vacuum impregnation is a process used in manufacturing to fill porous materials or components with a liquid or resin. It is commonly employed to enhance the properties of materials by improving their strength, sealing capability, or resistance to chemicals or corrosion. The process involves placing the porous material in a vacuum chamber and removing the air or gas trapped within its pores. Once a vacuum is established, a liquid or resin is introduced, and the vacuum is released, allowing the material to absorb the impregnating substance.

2. Role of Roots Vacuum Pumps: Roots vacuum pumps play a crucial role in the vacuum impregnation process by creating and maintaining the required vacuum conditions. Here’s how they contribute:

– Evacuation: Roots pumps are used to evacuate the impregnation chamber, removing the air and gas from within the pores of the porous material. By creating a vacuum, the trapped gases are extracted, creating a void space for the impregnating substance to penetrate.

– Pressure Control: Roots pumps help control the pressure within the impregnation chamber during different stages of the process. They can rapidly achieve and maintain the desired vacuum level, ensuring proper impregnation of the material and preventing the formation of air bubbles or voids.

– Gas Removal: Roots pumps effectively remove gases released from the impregnating substance during the impregnation process. As the liquid or resin fills the pores of the porous material, gases may be released due to the reaction or outgassing. The vacuum pump evacuates these gases, preventing their accumulation and ensuring complete impregnation.

3. Advantages of Roots Vacuum Pumps for Vacuum Impregnation:

– High Pumping Speed: Roots vacuum pumps have a high pumping speed, enabling rapid evacuation of the impregnation chamber. This reduces the overall impregnation cycle time, increasing manufacturing throughput and efficiency.

– Large Volume Handling: Roots pumps are capable of handling large volumes of gas, allowing them to evacuate chambers of different sizes effectively. This is advantageous when impregnating large or complex-shaped components that require a significant amount of impregnating substance.

– Continuous Operation: Roots pumps can operate continuously, maintaining the vacuum conditions required for impregnation throughout the process. This ensures consistent impregnation results and reduces the risk of incomplete impregnation or material defects.

– Compatibility with Impregnating Substances: Roots vacuum pumps are compatible with a wide range of impregnating substances, including resins, oils, solvents, and other liquids. They can handle different chemical compositions and provide a clean and efficient environment for the impregnation process.

4. Considerations for Vacuum Impregnation:

– Material Compatibility: It is essential to consider the compatibility of the porous material with the impregnating substance and the impregnation process itself. Some materials may require pre-treatment or surface preparation before impregnation. The choice of impregnating substance should also align with the material’s properties and intended application.

– Process Parameters: Vacuum impregnation involves controlling various process parameters, such as vacuum level, impregnation time, pressure release, and curing conditions. These parameters may vary depending on the material, impregnating substance, and desired impregnation results. Proper process optimization and control are crucial for achieving consistent and reliable impregnation outcomes.

– System Design: The design of the vacuum impregnation system should consider factors such as chamber size, gas flow rates, vacuum pump capacity, and pressure control mechanisms. Proper system design ensures efficient operation, reliable vacuum conditions, and effective impregnation of the porous material.

In summary, Roots vacuum pumps are well-suited for vacuum impregnation in manufacturing. Their high pumping speed, large volume handling capability, continuous operation, and compatibility with impregnating substances make them effective in creating and maintaining the required vacuum conditions for successful impregnation. By considering material compatibility, process parameters, and system design, Roots vacuum pumps contribute to the efficient and reliable impregnation of porous materials in various manufacturing applications.

Are Roots Vacuum Pumps Used in Industrial Applications?

Yes, Roots vacuum pumps are widely used in various industrial applications. Here’s a detailed explanation of their application in industrial settings:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are just a few examples of the industrial applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by Dream 2024-05-07