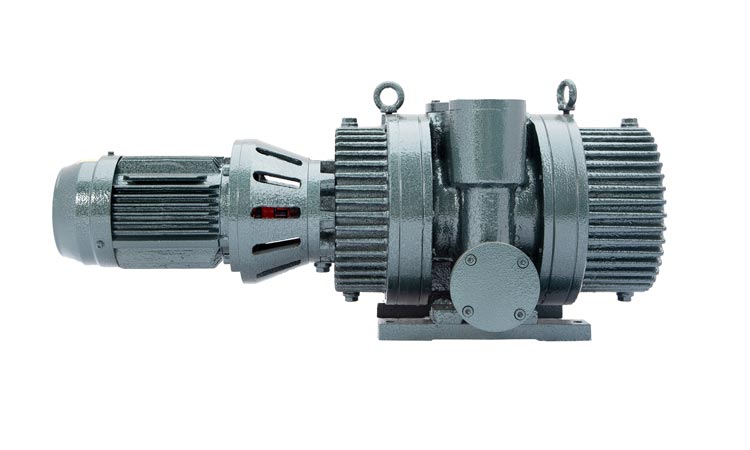

Product Description

Special structures working principles,suitable for operation in chemical industry,oil industry,food industry,electrical utility industry,pharmacy industry,textile industry and paper making industry,etc. The other industries that need vacuum drying,concentration,distilling,dehydration and filtering also need the water-ring vacuum pump. It can be use as a backing pump of Roots Pump.

VP roots vacuum pump is in the 50 Torr-micron high vacuum range has a large pumping speed and low cost of equipment, it can be combined with various vacuum pump consists of a vacuum unit. KMBD roots vacuum pump with 5 point bearing design unique, sealing the 5 bit machine, sealing double sealing structure + mechanical seal for maze, can realize non leakage, reduce maintenance and repair of the link, ensure the roots pump and durable. Synchronous helical gear and mounted on the driving end, both to ensure quiet and reliable operation, and can reduce the load of the rotor torque. Impeller and shaft integrally cast, can provide large size shaft, impeller and reduce the risk of damage. All contact with the sealing surface of the shaft end faces are polished to reduce wear and reduce the risk of leakage, high temperature high pressure casing, and double tank design, a variety of material selection, further to ensure that the use of the user in various working conditions. Typical application: chemical, petrochemical, plastics, semiconductors, wood mixture, food processing, vacuum furnace, vacuum booster system, vacuum drying, vacuum dewatering, vacuum packaging

| Model | Capacity | Ultimate Pressure | Power | speed |

| L/S | Pa | KW | RPM | |

| VP200 | 200 | 0.05 | 4 | 2900 |

| VP600 | 600 | 0.05 | 7.5 | 2900 |

About HangZhou Ever-power group(HZPT):

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ.

Please contact us with all relevant details to get the most accurate quotation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Custom |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure |

| Material: | Custom |

| Power Source: | Custom |

| Weight: | Custom |

| After-sales Service: | Installation Guide 1-Year Warranty |

How Do Roots Vacuum Pumps Affect the Efficiency of Vacuum Systems in Various Industries?

Roots vacuum pumps have a significant impact on the efficiency of vacuum systems across various industries. Here’s a detailed explanation:

1. Enhanced Vacuum Level:

– High Pumping Speed: Roots vacuum pumps are known for their high pumping speed, which refers to the rate at which they can evacuate gas from a system. By quickly removing gas molecules, these pumps help achieve and maintain a lower pressure, resulting in an enhanced vacuum level within the system. This increased vacuum level is crucial in industries such as semiconductor manufacturing, where precise control of pressure is necessary for optimal processing conditions.

– Improved Evacuation Time: With their rapid gas pumping capability, Roots vacuum pumps significantly reduce the evacuation time required to reach the desired vacuum level. This efficiency is particularly important in industries where time-sensitive processes are involved, such as vacuum drying, degassing, or impregnation, allowing for faster production cycles and increased productivity.

2. Increased Throughput:

– Continuous Operation: Roots vacuum pumps are designed for continuous operation, enabling uninterrupted gas removal from the vacuum system. Their robust construction and oil-free operation make them reliable and suitable for demanding industrial applications. The ability to maintain a consistent vacuum level without frequent stops or downtime contributes to increased system throughput and overall efficiency.

– Handling Large Volumes: Roots pumps are capable of handling large gas volumes due to their displacement principle. This makes them well-suited for industries that require the evacuation of substantial amounts of gas, such as in chemical processing, pharmaceutical manufacturing, or vacuum packaging. By efficiently evacuating large volumes of gas, Roots vacuum pumps facilitate higher production rates and improved process efficiency.

3. Improved Process Control:

– Stable Vacuum Level: Roots vacuum pumps help maintain a stable vacuum level within the system, which is essential for precise process control. By swiftly removing gas molecules, these pumps prevent pressure fluctuations and ensure a consistent environment for various manufacturing processes. This is particularly crucial in industries like thin film deposition, where maintaining a stable vacuum is crucial for achieving uniform coating thickness and quality.

– Reduced Contamination: Roots vacuum pumps operate without lubricating oil in the pumping chamber, minimizing the risk of oil contamination in the vacuum system. This is particularly advantageous in industries such as electronics, semiconductor fabrication, or research laboratories, where even trace amounts of contaminants can adversely affect product quality or experimental results. By providing clean and oil-free vacuum, Roots pumps contribute to improved process control, reduced yield loss, and enhanced product reliability.

4. Energy Efficiency:

– Lower Power Consumption: Roots vacuum pumps are designed to operate efficiently, consuming lower power compared to other types of vacuum pumps. This energy efficiency is beneficial in industries where vacuum systems are continuously operated, such as in chemical processing plants or industrial manufacturing facilities. By reducing power consumption, Roots pumps help lower operational costs and contribute to sustainable and environmentally friendly practices.

– Heat Dissipation: Roots pumps generate less heat during operation compared to certain other vacuum pump types. This is advantageous in industries where temperature control is critical, such as in semiconductor fabrication or vacuum furnaces. The reduced heat generation minimizes the need for additional cooling measures, improving overall energy efficiency and reducing operational costs.

In summary, Roots vacuum pumps significantly impact the efficiency of vacuum systems in various industries. They enhance the vacuum level, increase system throughput, improve process control, and contribute to energy savings. By providing high pumping speed, quick evacuation time, continuous operation, stable vacuum levels, reduced contamination risk, lower power consumption, and efficient heat dissipation, Roots vacuum pumps play a crucial role in optimizing the performance and productivity of vacuum systems across industries.

Are Roots Vacuum Pumps Used in Industrial Applications?

Yes, Roots vacuum pumps are widely used in various industrial applications. Here’s a detailed explanation of their application in industrial settings:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are just a few examples of the industrial applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by CX 2024-04-11

China Hot selling Stainless Steel Two Stage Vacuum Pump Lobe Rotary Piston Pump Gear Rotary Oil Pump with Moving Wheel Cart vacuum pump and compressor

Product Description

21 Years Of Experience. 3-7 days delivery, 3 Years Warranty , Reasonable Price And Best Service, CE Certificated Products. Advanced Technology. Please contact us for the offer.

Product Description

Description:

Rotary lobe pumps are positive-displacement type pumps that use 2 or more lobes rotating around parallel shafts in the pump’s body to move liquids. They are widely used in the hygienic processing industries, including food & beverage processing and biopharmaceutical manufacturing.

Working Principle of Rotary Lobe Pump:

The rotary lobe pumps, we also called them lobe rotor pumps. They are 1 popular transfer pump to conveying the food, beverage, pulp and paper, chemical, pharmaceutical and so on. The rotor lobe pump relies on 2 synchronously rotating rotors that generate suction (vacuum) at the inlet during the rotation. Thereby sucking in the material to be conveyed. Both rotors split the rotor chamber into different spaces. Then operate in the order of 1-2-3-4. The medium is delivered to the discharge port. In this cycle, the medium (material) is continuously transported out by the source.

Different Kind of Lobe Options for the Rotor Lobe Pump

1. Single Lobed Rotor: More suitable for conveying media which containing large granular materials. The breaking rate of large granular materials is low. But on other hand it is not popular 1 for used, Because its pulsation is large and pressure is low, also the volume is small for the space of transferred materials.

2. Two-Lobed Rotor (Butterfly Rotor) More suitable for conveying media which containing small and medium-size granular materials. The breaking rate to these materials is low and getting slightly pulsating. The volume is a little less than the three-lobed rotor for the space of transferred materials.

3. Three-Lobed Rotor It is widely used in 1 rotor. The volume is bigger than other type of rotors for the space of transferred materials. Also, each performance is higher than other rotors. Just, it has a certain rate of breakage to the particulate materials on the transport way.

4. Multi-Lobed Rotor(4-12) The volume is smaller for the space of transferred materials and breaking rate higher when the quantity of rotary vane of rotor be increased, Just the transport way more stable.

Character:

1,There Is A Certain Gap Between Rotor And Rotor, No Friction Coefficient, So Pump Have A Long Service Life Time.

2, It Is Easy To Install And Disassemble, And It Is Convenient To Maintain, clean . There Is Less Wearing Parts.

3, High Efficiency And Energy Saving, Stable Transportation, Low Failure Rate, No Leak Sealing And Low Noise.

4, The Viscosity Of The Transportable Medium Is, ≤2000000 CP, And The Pump Can Transfer Slurry Containing 70% Solids.

5, It Can Transport Gas, Liquid And CZPT Three-Phase Mixture Materials.

6, With FD, The Flow Can Be Adjusted At Will, And The Pump Can Be Used As A General Metering Pump.

7, If you need, We Can Do The Pump With Heating Jacket.

8, Applicable Temperature: -50 °C, -250 °C.

9, Types Of Inlet/Outlet Connection: Flange Joint, Threaded Connection; Quick Connection.

10,Seal Type: Mechanical Seal And Packing Seal.

Lobe Pump Scope Of Application.

Dairy Products: Yogurt, Cream, Ice Cream, Cheese And Whey.

Beverages: Beer, Wort, Yeast, Soft Drinks, Fruit Concentrates, Fruit Drinks.

Food: Tomato Sauce, Vegetable Paste, Seasoning, Sweeteners, Yeast Paste, Salad, Meat Emulsion, Edible Oil.

Candy: Syrup, Cream Stuffing, Fruit Purée, Fruit Filling, Pudding, Jam, Jelly, Chocolate.

Cosmetics: Creams And Lotions, Hair Gels, Hair Dyes, Essential Oils.

Drugs: Pill, Extract, Emulsion, Paste.

Chemicals: Fats, Solvents, Resins And Polymers, dyes…

ADVANTAGES OF ROTARY LOBE PUMPS

Since the pump’s lobes do not come into contact with each other, lobe pumps can move solids suspended in slurries (such as cherries or olives in food processing applications) without product damage. The gentle pump action further minimizes product degradation. Can handle larger sized particles than may be pumped with other types of positive displacement pumps. It may be easily cleaned using either clean-in-place (CIP) or steam-in-place (SIP) methods, making them ideal for hygienic processing applications. Highly efficient for pumping very viscous liquids. Offer accurate and consistent fluid output that is unaffected by changes in head pressure, assuming sufficient fluid viscosity. The fluid flow can be increased or decreased by controlling the drive speed. If wetted, rotary lobe pumps are also self-priming, and can run dry for long periods of time (assuming the pump’s seals are lubricated). Generally easy to maintain.

|

Product Name: |

Sanitary Stainless Steel Rotor Rotary Lobe Pump |

|

Description: |

Designed according to 3A standard, widely used for transfer viscous media in the food-processing, cosemtics and pharmaceutical |

|

Construction: |

Horizontal Ace series, diffirent rotor shapes(single rotro,tri-lobe rotors and butterfly type rotors) |

|

Material: |

SS304/SS316 |

|

Seal Material: |

CZPT (Standard, approval) |

|

Max. Flow: |

43000Liter/h |

|

Max.pressure: |

10bar |

|

Speed |

1-1000 rmp |

|

Rotor Type: |

2-leaves, 3-leaves, butterfly, signal butterfly |

|

Mechanical seal: |

SIC/SiC/EPDM(Standard) |

|

Motor power: |

0.75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, …22KW |

|

Sealing option: |

Sanitary single mechanical seal/Double mechanical seal with cooling system |

|

Voltage: |

220V, 380V(110-480v) |

|

Motor: |

ABB, Siemens,Our Domestic Brand,50hz/ 60hz |

|

Surface treatment: |

Inner polished and Sandblast outside |

|

connection: |

Clamp, Thread, weld, Flange |

|

Availably standard: |

DIN, SMS, 3A, RJT, ISO/IDF |

|

Operated: |

Electic |

|

Application scope: |

Dairy, food, beverage, pharmacy, cosmetic, etc |

|

Packaging Details: |

Plywood case |

|

Delivery details: |

Usually within1-7 days after receiving T/T down payment |

|

We can customize the Lobe Pump according to customer requirements. |

|

|

Technical Parameters |

||||

|

Model |

Capacity/Per centum rotate (L) |

Speed(RPM) |

Flow(L/H) |

Power(KW) |

|

ACE-3R |

3L |

100-500 |

300-800 |

0.55 |

|

ACE-6R |

6L |

100-500 |

650-1600 |

0.75 |

|

ACE-8R |

8L |

100-500 |

850-2160 |

1.5 |

|

ACE-12R |

12L |

100-500 |

1300-3200 |

2.2 |

|

ACE-20R |

20L |

100-500 |

2100-5400 |

3 |

|

ACE-30R |

30L |

100-500 |

3200-6400 |

4 |

|

ACE-36R |

36L |

100-500 |

3800-7600 |

4 |

|

ACE-52R |

52L |

100-500 |

5600-11000 |

5.5 |

|

ACE-66R |

66L |

100-500 |

7100-14000 |

7.5 |

|

ACE-78R |

78L |

100-500 |

9000-18000 |

7.5 |

|

ACE-100R |

100L |

100-500 |

11000-22000 |

11 |

|

ACE-135R |

135L |

100-500 |

15000-30000 |

15 |

|

ACE-160R |

160L |

100-500 |

17000-34000 |

18.5 |

|

ACE-200R |

200L |

100-500 |

21600-43000 |

22 |

Detailed Photos

Packaging & Shipping

Other pumps

Certifications

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6.Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Video Technical Support, Online Support |

|---|---|

| Warranty: | 2 Years |

| Mesh Form: | External Engaged |

| Tooth Flank: | Stainless Steel Rotary Lobe |

| Tooth Curve: | Stainless Steel Rotary Lobe |

| Power: | Electric |

| Samples: |

US$ 850/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Types of vacuum pumps

A vacuum pump is a device that draws gas molecules from a sealed volume and maintains a partial vacuum. Its job is to create a vacuum in a volume, usually one of several. There are several types of vacuum pumps, such as root pumps, diaphragm pumps, rotary piston pumps, and self-priming centrifugal pumps.

The diaphragm pump is a dry positive displacement vacuum pump

Diaphragm pumps are a versatile type of vacuum pump. They can be installed in a variety of scenarios including container emptying, positive suction, and simultaneous fluid mixing. Their performance depends on the stiffness and durability of the diaphragm, which in turn depends on the material.

They have good performance when running in dry mode. Diaphragm pumps work very similarly to the human heart, which is why they are often used to create artificial hearts. In addition, the diaphragm pump is self-priming and has high efficiency. They are also capable of handling the most viscous liquids and are used in almost all industries.

However, this type of pump has several disadvantages. One of them is that they are difficult to restart after a power outage. Another disadvantage is that they can generate a lot of heat. Fortunately, this heat is carried away by airflow. However, this heat builds up in the multistage pump. If this happens, the diaphragm or motor may be damaged. Diaphragm pumps operating in two or more stages should be fitted with solenoid valves to maintain vacuum stability.

Diaphragm pumps are a good choice for drying processes where hygiene is important. These pumps have check valves and rubber or Teflon diaphragms. Diaphragm pumps are also ideal for high viscosity applications where shear sensitivity is important.

Roots pumps are dry method centrifugal pumps

Roots pumps use a vane rotor pump with two counter-rotating vanes that move in opposite directions to move the gas. They are often the first choice for high-throughput process applications. Depending on the size and number of blades, they can withstand up to 10 Torr.

Centrifugal pumps have several advantages, including the ability to handle corrosive fluids and high temperatures. However, when choosing a pump, it is essential to choose a reputable manufacturer. These companies will be able to advise you on the best pump design for your needs and provide excellent after-sales support. Roots pumps can be used in a wide range of industrial applications including chemical, food, and biotechnology.

The Roots pump is a dry centrifugal pump whose geometry enables it to achieve high compression ratios. The screw rotors are synchronized by a set of timing gears that allow gas to pass in both directions and create a compressed state in the chamber. The pre-compressed gas is discharged through a pressure connection and cooled with water. Some pumps are also able to accept additional cooling gas, but this should be done with caution.

The size of the impeller plays an important role in determining the pump head. The impeller diameter determines how high the pump can lift the liquid. Impeller speed also affects the head. Since the head is proportional to the specific gravity of the liquid, the available suction pressure will be proportional to the density of the liquid. The density of water is about 1.2 kg/m3, and the suction pressure of the centrifugal pump is not enough to lift the water.

The rotary vane pump is a self-priming centrifugal pump

A rotary vane pump is a centrifugal pump with a circular pump head and a cycloid cam that supports the rotor. The rotor is close to the cam wall, and two side plates seal the rotor. Vanes in vane pumps are installed in these cavities, and the rotor rotates at high speed, pushing fluid in and out of the pump. The pump offers several advantages, including a reversible design and the ability to handle a wide variety of clean fluids.

Agknx Pumps manufactures a wide range of vane pumps that combine high performance, low cost, and easy maintenance. These pumps handle medium to high viscosity liquids up to 500 degrees Fahrenheit and 200,000 SSU.

The suction side of the rotary vane pump has a discharge port, and the valve prevents the backflow of the discharge air. When the maximum pressure is reached, the outlet valve closes to prevent the backflow of exhaust gas. The mechanical separation step separates the oil from the gas in the pump circuit and returns the remaining oil particles to the sump. The float valve then reintroduces these oil particles into the oil circuit of the pump. The gas produced is almost oil-free and can be blown out of a pipe or hose.

Rotary vane pumps are self-priming positive displacement pumps commonly used in hydraulic, aeration, and vacuum systems. Unlike gear pumps, rotary vane pumps can maintain high-pressure levels while using relatively low suction pressures. The pump is also very effective when pumping viscous or high-viscosity liquids.

Rotary piston pumps are dry method positive displacement pumps

Rotary piston pumps are dry positive displacement pumps designed to deliver high-viscosity fluids. They are capable of pumping a variety of liquids and can run dry without damaging the liquid. Rotary piston pumps are available in a variety of designs. Some are single shafts, some are two shafts and four bearings.

Positive displacement pumps operate slower than centrifugal pumps. This feature makes the positive displacement pump more sensitive to wear. Piston and plunger reciprocating pumps are particularly prone to wear. For more demanding applications, progressive cavity, diaphragm or lobe pumps may be a better choice.

Positive displacement pumps are typically used to pump high-viscosity fluids. This is because the pump relies on a mechanical seal between the rotating elements and the pump casing. As a result, when fluids have low viscosity, their performance is limited. Additionally, low viscosity fluids can cause valve slippage.

These pumps have a piston/plunger arrangement using stainless steel rotors. Piston/piston pumps have two cavities on the suction side. The fluid then flows from one chamber to the other through a helical motion. This results in very low shear and pulsation rates. The pump is usually installed in a cylindrical housing.

Rotary vane pump corrosion resistance

Rotary vane vacuum pumps are designed for use in a variety of industries. They feature plasma-treated corrosion-resistant parts and anti-suck-back valves to help reduce the number of corrosive vapors entering the pump. These pumps are commonly used in freeze dryers, vacuum ovens, and degassing processes. The high flow rates they provide in their working vacuum allow them to speed up processes and reduce the time it takes to run them. Plus, they have energy-efficient motors and silent volume. <br/While rotary vane vacuum pumps are relatively corrosion resistant, they should not be used for aggressive chemicals. For these chemicals, the most suitable pump is the chemical mixing pump, which combines two types of pumps to improve corrosion resistance. If the application requires a more powerful pump, a progressive cavity pump (eg VACUU*PURE 10C) is suitable.

Oil seals used in rotary vane pumps are important to pump performance. The oil seal prevents corrosion of the aluminum parts of the rotary vane pump and prolongs the service life. Most rotary vane vacuum pumps have a standard set of components, although each component may have different oil seals.

Rotary vane vacuum pumps are the most common type of positive displacement pump. They provide quiet operation and long service life. They are also reliable and inexpensive and can be used in a variety of applications.

Roots pumps are primarily used as a vacuum booster

Root vacuum pumps are mainly used as vacuum boosters in industrial applications. They need a thorough understanding of operating principles and proper maintenance to function properly. This course is an introduction to Roots vacuum pumps, covering topics such as pump principles, multi-stage pumps, temperature effects, gas cooling, and maintenance.

Roots pumps have many advantages, including compact and quiet operation. They do not generate particles and have a long service life. They also don’t require oil and have a small footprint. However, Roots pumps have several disadvantages, including relatively high maintenance costs and low pumping speeds near atmospheric pressure.

Root vacuum pumps are often used with rotary vane vacuum pumps. They work on the same principle, the air enters a conveying unit formed by two rolling pistons in the housing. The piston heads are separated from each other, and the air passes through the unit without being reduced until it is discharged. When the air in the next unit reaches a higher absolute pressure, it is expelled from the last unit.

Roots pumps can be classified as sheathed or sealed. Roots pumps with sealed motors are suitable for pumping toxic gases. They have less clearance between the stator and motor rotor and have a sealed tank.

editor by CX 2024-04-09

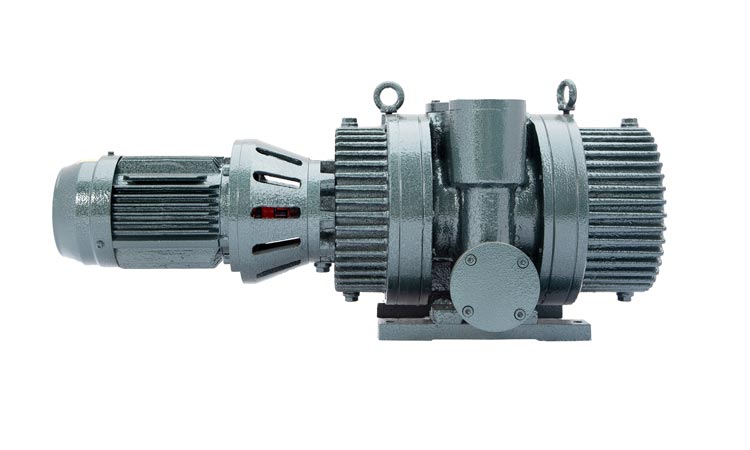

China supplier Gear Pump Roots Vacuum Pumps vacuum pump electric

Product Description

Special structures working principles,suitable for operation in chemical industry,oil industry,food industry,electrical utility industry,pharmacy industry,textile industry and paper making industry,etc. The other industries that need vacuum drying,concentration,distilling,dehydration and filtering also need the water-ring vacuum pump. It can be use as a backing pump of Roots Pump.

VP roots vacuum pump is in the 50 Torr-micron high vacuum range has a large pumping speed and low cost of equipment, it can be combined with various vacuum pump consists of a vacuum unit. KMBD roots vacuum pump with 5 point bearing design unique, sealing the 5 bit machine, sealing double sealing structure + mechanical seal for maze, can realize non leakage, reduce maintenance and repair of the link, ensure the roots pump and durable. Synchronous helical gear and mounted on the driving end, both to ensure quiet and reliable operation, and can reduce the load of the rotor torque. Impeller and shaft integrally cast, can provide large size shaft, impeller and reduce the risk of damage. All contact with the sealing surface of the shaft end faces are polished to reduce wear and reduce the risk of leakage, high temperature high pressure casing, and double tank design, a variety of material selection, further to ensure that the use of the user in various working conditions. Typical application: chemical, petrochemical, plastics, semiconductors, wood mixture, food processing, vacuum furnace, vacuum booster system, vacuum drying, vacuum dewatering, vacuum packaging

| Model | Capacity | Ultimate Pressure | Power | speed |

| L/S | Pa | KW | RPM | |

| VP200 | 200 | 0.05 | 4 | 2900 |

| VP600 | 600 | 0.05 | 7.5 | 2900 |

About HangZhou Ever-power group(HZPT):

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ.

Please contact us with all relevant details to get the most accurate quotation.

| Type: | Custom |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure |

| Material: | Custom |

| Power Source: | Custom |

| Weight: | Custom |

| After-sales Service: | Installation Guide 1-Year Warranty |

How Do Roots Vacuum Pumps Affect the Efficiency of Vacuum Systems in Various Industries?

Roots vacuum pumps have a significant impact on the efficiency of vacuum systems across various industries. Here’s a detailed explanation:

1. Enhanced Vacuum Level:

– High Pumping Speed: Roots vacuum pumps are known for their high pumping speed, which refers to the rate at which they can evacuate gas from a system. By quickly removing gas molecules, these pumps help achieve and maintain a lower pressure, resulting in an enhanced vacuum level within the system. This increased vacuum level is crucial in industries such as semiconductor manufacturing, where precise control of pressure is necessary for optimal processing conditions.

– Improved Evacuation Time: With their rapid gas pumping capability, Roots vacuum pumps significantly reduce the evacuation time required to reach the desired vacuum level. This efficiency is particularly important in industries where time-sensitive processes are involved, such as vacuum drying, degassing, or impregnation, allowing for faster production cycles and increased productivity.

2. Increased Throughput:

– Continuous Operation: Roots vacuum pumps are designed for continuous operation, enabling uninterrupted gas removal from the vacuum system. Their robust construction and oil-free operation make them reliable and suitable for demanding industrial applications. The ability to maintain a consistent vacuum level without frequent stops or downtime contributes to increased system throughput and overall efficiency.

– Handling Large Volumes: Roots pumps are capable of handling large gas volumes due to their displacement principle. This makes them well-suited for industries that require the evacuation of substantial amounts of gas, such as in chemical processing, pharmaceutical manufacturing, or vacuum packaging. By efficiently evacuating large volumes of gas, Roots vacuum pumps facilitate higher production rates and improved process efficiency.

3. Improved Process Control:

– Stable Vacuum Level: Roots vacuum pumps help maintain a stable vacuum level within the system, which is essential for precise process control. By swiftly removing gas molecules, these pumps prevent pressure fluctuations and ensure a consistent environment for various manufacturing processes. This is particularly crucial in industries like thin film deposition, where maintaining a stable vacuum is crucial for achieving uniform coating thickness and quality.

– Reduced Contamination: Roots vacuum pumps operate without lubricating oil in the pumping chamber, minimizing the risk of oil contamination in the vacuum system. This is particularly advantageous in industries such as electronics, semiconductor fabrication, or research laboratories, where even trace amounts of contaminants can adversely affect product quality or experimental results. By providing clean and oil-free vacuum, Roots pumps contribute to improved process control, reduced yield loss, and enhanced product reliability.

4. Energy Efficiency:

– Lower Power Consumption: Roots vacuum pumps are designed to operate efficiently, consuming lower power compared to other types of vacuum pumps. This energy efficiency is beneficial in industries where vacuum systems are continuously operated, such as in chemical processing plants or industrial manufacturing facilities. By reducing power consumption, Roots pumps help lower operational costs and contribute to sustainable and environmentally friendly practices.

– Heat Dissipation: Roots pumps generate less heat during operation compared to certain other vacuum pump types. This is advantageous in industries where temperature control is critical, such as in semiconductor fabrication or vacuum furnaces. The reduced heat generation minimizes the need for additional cooling measures, improving overall energy efficiency and reducing operational costs.

In summary, Roots vacuum pumps significantly impact the efficiency of vacuum systems in various industries. They enhance the vacuum level, increase system throughput, improve process control, and contribute to energy savings. By providing high pumping speed, quick evacuation time, continuous operation, stable vacuum levels, reduced contamination risk, lower power consumption, and efficient heat dissipation, Roots vacuum pumps play a crucial role in optimizing the performance and productivity of vacuum systems across industries.

What Are the Primary Applications of Roots Vacuum Pumps?

Roots vacuum pumps, also known as Roots blowers or rotary lobe pumps, are utilized in a variety of industrial applications where efficient and reliable vacuum generation is required. Here’s a detailed explanation of the primary applications of Roots vacuum pumps:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are some of the primary applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by CX 2023-11-21

China wholesaler High Pressure Discharge Melt Gear Pump a/c vacuum pump

Product Description

Specifications

1,polymer melt gear pump

2, fit for large capacity output

3, fit for very high or low viscosity polymer

Large flow rate polymer melt gear pump for reactor as discharge pump

GM-G series of polymer melt gear pump is designed with a large entrance , suitable for the high temperature and high viscosity polymer melt conveying reaction, such as resin, chemical fiber industry, generally installed on the lower part of the reaction kettle, used as discharge pump.This series of melt gear pump has good self-priming performance, can be used in the vacuum reaction condition, the polymer material conveying and pressurization.

This GM-G series large flow rate polymer melt gear pump used under the reaction kettle/reactor as a discharge pump, you can see the following pictures

Main application fields:

For Processing:

PET PBT

PA6 PA66 PA12

LDPE LLDPE HDPE HMWPE

PP EVA PB

PS HIPS ABS SAN

PC PEK

PMMA POM TPU

Other high viscosity Polymers

Product show

The characteristic of this GM-G series polymer melt gear pump under the reaction kettle as discharge pump.

1)it can be used on high temperature (350ºC),high pressure(15MPa),high viscosity (40,000Pas)working condition.

2)The pressure flow pulsation is very small, and even can achieve linear output flow,easy to control

3)Good self-priming performance, can be used in the entrance with the operation condition of vacuum (0.05 ~ 0.09 MPa)

4)Precise structure, high precision, long service life

Technical data:

Viscosity: 500~40000Pas(500,000~40,000,000cP)

Suction side pressure : Vacuum(-0.05~-0.09MPa)~10MPa

Discharge side pressure: 0~15MPa

Differential pressure: 15MPa

Temperature: ≤350ºC

Heating method: Fully heating medium Jacketed

HT medium pressure: ≤1.6MPa

Pump type and parameter

Sealing structure

1)the melt dynamic seal and packing seal

2)Single/double side machanical seal

3)With cooling melt dynamic seal

4)High temperature resistant packing seal

Installation way: GM-HG series melt gear pump generaaly is installed under the reaction kettle, it is used as the material discharge pump, usually arranged horizontally.

Drive mode:motor + reducer + universal coupling

Commissioning

We provide the operation manual for customers to gudie to install the screen changer, and at the requirement of user, salers should send technician to install and commissioning the die at site of Buyers, expenses of the trip should be borne by Buyers.

After-sales service

12 months with proper operation by user, all the spare parts shall be replaced free of charge under guarantee period, fee for transportation and packing will be borne by users.

| Mesh Form: | External Engaged |

|---|---|

| Tooth Flank: | Skew Tooth |

| Power: | Electric |

| Type: | Normal Line Gear Pump |

| Applications: | Thermoplastic Transportation |

| Certification: | CE |

How to check the vacuum pump

A vacuum pump is a machine that draws gas molecules from a volume and maintains a partial vacuum. Its main job is to create a relative vacuum within the stated capabilities. If your vacuum pump isn’t working properly, it may need service. Read on to learn more about the types of vacuum pumps and how to check them.

Principle of industrial vacuum pump

Industrial vacuum pumps are used in industrial processes that require vacuum. These pumps are designed to generate, improve and maintain vacuum. Learn about the different types of industrial vacuum technology. You can start by reading about the most common types of industrial vacuum pumps. These pumps can be used in a variety of industrial processes from cleaning to manufacturing.

Regardless of the technology used to manufacture these pumps, the basic principles behind their operation are the same. The speed and mass flow of the pump will determine its capacity and suitability. A faster flow rate will minimize the time it takes for the machine to empty. Another important factor to consider is the type of vacuum you need.

A liquid ring vacuum pump is an industrial pump that uses a ring of liquid to form a seal. This type of pump is best suited for applications with high vapor loads and high liquid carry-over. Liquid ring vacuum pumps can be divided into two categories: liquid ring vacuum pumps and scroll vacuum pumps.

Industrial vacuum pumps work by removing gas molecules from a chamber. The partial vacuum created allows material to flow through the void. As more molecules are removed, the pressure in the chamber decreases, releasing energy that can be used for a variety of different purposes.

The most common use of industrial vacuum pumps is for electric lights. In these lamps, a vacuum pump removes the gas, causing the bulb to light up. Energy from the vacuum is also used in aircraft to power instruments. In addition to powering industrial vacuum cleaners, they are used in a variety of other environments.

High-performance industrial vacuum systems require specific materials that can withstand extreme pressure. This means that the materials used in these systems need to be properly checked. They must also be free of organic debris and other contaminants before they can be safely placed in the chamber.

Types of vacuum pumps

There are various types of vacuum pumps. Which one to choose should depend on the purpose of the pump and the degree of vacuum that must be achieved. It is mainly divided into three categories: rough vacuum or low vacuum, high vacuum and ultra-high vacuum. They all have varying degrees of scarcity. The higher the pressure, the fewer molecules per cubic centimeter. This in turn improves vacuum quality.

The vacuum pump is critical to the operation of the vacuum system. These devices are divided into three main categories according to their working pressure range. These pumps have different characteristics and technologies that make them ideal for specific applications. The choice of vacuum pump required for a particular application depends on how much vacuum you need, and how much power you are willing to spend.

Vacuum pumps are used in a variety of industrial and scientific processes. Their main function is to remove gas molecules from the sealed volume, leaving a partial vacuum. There are many different types of vacuum pumps, including rotary piston, liquid ring and scroll vacuum pumps. In addition, turbomolecular pumps are used.

Dry vacuum pumps are more expensive than wet vacuum pumps. Wet vacuum pumps use oil as their lubricating fluid. Different types of oils are used depending on the application. Some wet pumps have additional features, including contaminant filtration. However, wet systems have one major disadvantage: the contact between oil and fluid. To avoid this, oil separators are usually used.

There are several different types of vacuum pumps. The basic type is the positive displacement pump. It operates by expanding the chamber and removing gas molecules. The intake valve draws fluid into the chamber, while the exhaust valve opens when the chamber is at maximum expansion. This cycle repeats several times per second. Positive displacement pumps are often used in multistage vacuum systems.

Maintenance of vacuum pump

Regular maintenance is very important to ensure the long-term effective use of the vacuum pump. One way to ensure proper pump performance is to change the oil regularly. Pump oil may be contaminated by vapor condensation. To avoid this problem, close the inlet valve for 20 to 30 minutes before applying vacuum. It is also important to install an inlet cold trap to protect the pump from corrosive vapors.

Another way to prolong the life of your vacuum pump is to periodically remove any solvent in it. This step reduces internal corrosion and prevents premature pump failure. During maintenance, be sure to disconnect the power supply to the vacuum pump. After cleaning, store it in a dry and safe place. The pump should also be disposed of in accordance with local regulations.

Vacuum pumps may require frequent oil changes, especially when used in wet chemistry. The standard rule is to change the oil after 3,000 hours of use, but some pumps require more frequent oil changes. It is also important to clean the oil regularly, as dirty or discolored oil can affect the performance of the pump.

Vacuum pumps are often equipped with on-site glass to allow the user to visually check the oil level. Clean oil will appear transparent, while dirty oil will appear darker. Frequent oil changes are essential, as oil changes can help spot various potential problems. Changes in vacuum pump performance or strange noises are also good indicators of a problem.

After an oil change, the vacuum pump should be cleaned thoroughly with a soft cloth and mild degreaser. Oil changes should take less than ten minutes, and they will extend the life of your equipment. Additionally, the outside of the pump should be wiped with a cloth or rag.

The pump must be properly vented to avoid internal corrosion. If possible, place the pump away from hot equipment or rooms. Overheating can reduce the viscosity of the oil and cause premature pump failure. In addition, it can lead to overwork of other expensive scientific equipment. Heat can also cause cracked rubber parts and oil leaks.

Signs of damage to the vacuum pump

A bad vacuum pump can cause a variety of automotive problems, including poor fuel economy, difficult braking, undercarriage oil leaks, and faulty air conditioning. If any of these problems occur, call a mechanic to check your vehicle’s vacuum pump. You can also check the air conditioner and brake pedal to see if they are working properly.

A loud noise from the pump can also be a symptom of a malfunction. These noises are often caused by the aging and accumulated wear of specific components. If this is the case, the diaphragm, valve plate or seals may need to be replaced. However, if the noise is coming from bearings or other areas, more extensive repairs may be required. Additionally, dust and other contaminants can enter the pump chamber, which can degrade pump performance.

If the vacuum pump won’t start, it could be a blown fuse or a power or voltage problem. Other common causes are flow restrictions or improper installation at the entrance. Also, the vacuum pump may be damaged or the capacitors may be of poor quality. It’s not always easy to tell if a vacuum pump is leaking oil, but a greasy transmission can indicate a vacuum pump failure.

A leaking vacuum pump can also hiss when the car’s engine is running. If you hear it, check the hoses and connections to make sure there are no leaks. A vacuum leak may indicate a faulty vacuum pump, so you need to replace it as soon as possible.

Checking end pressure is easy, but a pressure gauge can also serve as a sign. You can also check for pump vibration by running a short procedure. Excessive vibration can be subtle, but it can greatly affect your process. If you notice excessive pump vibration, you should contact a professional immediately.

Poor pump performance can cause many problems for your company. A bad vacuum pump not only wastes material, it also damages your tools and reputation.

editor by CX 2023-11-13

China Professional Oilgear Hydraulic Pump Variable Plunger Pvm-130/75/2564-A2ub-Rsfy-P-1nnsn Gear Pump/High Pressure Pump/Vacuum Pump wholesaler

Product Description

American OILGEAR plunger pump PFCS series PVV series PVK series PVG series PVW series PVM series

PVM hydraulic pump – high performance open axial piston pump

PVWH hydraulic pump – low horsepower high performance open axial piston pump

PVWW hydraulic pump – low horsepower high performance open axial piston pump for low viscosity or water-containing oil

PVWC hydraulic pump-low horsepower high performance closed axial piston pump

PVG hydraulic pump – mid-range horsepower high performance open axial piston pump

PVK hydraulic pump-mid-range-high-end horsepower high-performance open axial piston pump

PVV hydraulic pump – high horsepower high performance open axial piston pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFCM hydraulic pump – high pressure and high load open multi-stage quantitative output pump

PFCS hydraulic pump – high pressure and high load open multi-stage quantitative output pump

DN type hydraulic pump-variable radial piston pump

PVG-048-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LSFY-P-1NNSN

PVG-075-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-RDFZ-P-1NNSN-CN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-RGFK-P-1NN/H100SN-NN

PVG-130-F1UV-RDFZ-P-1NNNN

PVG-130-F1UV-LDFY-P-1NN/H050NN-CP

PVG-100-F1UV-LDFY-P-1NNSN-CP

PVG-100-FIUV-LGFZ-P-1NNSN-NN

PVG-048-F1UV-LGFY-N-1NNNN-AA/05

PVG-100-F1UV-LGFY-N-20RSA

PVG-075-F1UV-LSFY-P-1NNSN-NN

PVG-075-F1UV-RDFY-N-1NNNN-AA/05

PVG-065-F1UB-RGFY-P-1NNNN-NN

PVG-065-F1UP-RGFY-P-1NNNN-NN (Test Equipment)

PVG-065-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-RGFK-P-1NN/G047SN/827

PVG-100-FIUV-LGFZ-P-1NNSN

PVG-130-E1UB-LSFY-P-1NNSN/704 (PVG-130-F1UB-LSFY-P-1NNSN/844)

PVG-130-F1UB-LSFY-P-1NNSN/844

PVG-130-F1UB-RSFY-P-1NNSN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-LGFK-P-1NN/FNN-NN

PVG-150-A1UV-LGFY-P-1NNNN

PVK-140-A1UV-RDFS-P-1NNSN-CP/133 for Komatsu

PVK-270-B1UV-RDFY-P-1NNSN-CP

PVM-011-BIUB-RSAY-P-1NNNN

PVM-046-A1UB-RSFY-P-1NNNN

PVM-130-A2UV-RSFY-P-1NNSN

PVM-130-A2UV-RSFY-P-1NNSN (for thin oil stations on chemical plants)

PVV-250-B1BV-RSFY-P-1NNSN-NN

PVV-250-B1UV-RSFY-F-100SB

PVWH-06-LSAY-MNSA

Upgrade (PVWJ-014-A1UV-LSAY-M-NNSA)

PVWH-11-LDFS-CFNN-THCPP17571C

PVWJ-011-A1UV-RSAY-P-1NNSN

PVL Hydraulic Pump-Variable Axial Piston Pump

FCS Hydraulic Pump – Swing Plate Driven Inspection Valve Type Grading Quantitative PumpAmerican OILGEAR plunger pump PFCS series PVV series PVK series PVG series PVW series PVM series

PVM hydraulic pump – high performance open axial piston pump

PVWH hydraulic pump – low horsepower high performance open axial piston pump

PVWW hydraulic pump – low horsepower high performance open axial piston pump for low viscosity or water-containing oil

PVWC hydraulic pump-low horsepower high performance closed axial piston pump

PVG hydraulic pump – mid-range horsepower high performance open axial piston pump

PVK hydraulic pump-mid-range-high-end horsepower high-performance open axial piston pump

PVV hydraulic pump – high horsepower high performance open axial piston pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFCM hydraulic pump – high pressure and high load open multi-stage quantitative output pump

PFCS hydraulic pump – high pressure and high load open multi-stage quantitative output pump

DN type hydraulic pump-variable radial piston pump

PVG-048-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LSFY-P-1NNSN

PVG-075-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-RDFZ-P-1NNSN-CN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-RGFK-P-1NN/H100SN-NN

PVG-130-F1UV-RDFZ-P-1NNNN

PVG-130-F1UV-LDFY-P-1NN/H050NN-CP

PVG-100-F1UV-LDFY-P-1NNSN-CP

PVG-100-FIUV-LGFZ-P-1NNSN-NN

PVG-048-F1UV-LGFY-N-1NNNN-AA/05

PVG-100-F1UV-LGFY-N-20RSA

PVG-075-F1UV-LSFY-P-1NNSN-NN

PVG-075-F1UV-RDFY-N-1NNNN-AA/05

PVG-065-F1UB-RGFY-P-1NNNN-NN

PVG-065-F1UP-RGFY-P-1NNNN-NN (Test Equipment)

PVG-065-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-RGFK-P-1NN/G047SN/827

PVG-100-FIUV-LGFZ-P-1NNSN

PVG-130-E1UB-LSFY-P-1NNSN/704 (PVG-130-F1UB-LSFY-P-1NNSN/844)

PVG-130-F1UB-LSFY-P-1NNSN/844

PVG-130-F1UB-RSFY-P-1NNSN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-LGFK-P-1NN/FNN-NN

PVG-150-A1UV-LGFY-P-1NNNN

PVK-140-A1UV-RDFS-P-1NNSN-CP/133 for Komatsu

PVK-270-B1UV-RDFY-P-1NNSN-CP

PVM-011-BIUB-RSAY-P-1NNNN

PVM-046-A1UB-RSFY-P-1NNNN

PVM-130-A2UV-RSFY-P-1NNSN

PVM-130-A2UV-RSFY-P-1NNSN (for thin oil stations on chemical plants)

PVV-250-B1BV-RSFY-P-1NNSN-NN

PVV-250-B1UV-RSFY-F-100SB

PVWH-06-LSAY-MNSA

Upgrade (PVWJ-014-A1UV-LSAY-M-NNSA)

PVWH-11-LDFS-CFNN-THCPP17571C

PVWJ-011-A1UV-RSAY-P-1NNSN

PVL Hydraulic Pump-Variable Axial Piston Pump

FCS Hydraulic Pump – Swing Plate Driven Inspection Valve Type Grading Quantitative Pump

| Type: | Gear Pump |

|---|---|

| Transport Package: | Standard Wooden Box or Carton |

| Specification: | 35*35*40 |

| Origin: | USA |

Types of vacuum pumps

A vacuum pump is a device that draws gas molecules from a sealed volume and maintains a partial vacuum. Its job is to create a vacuum in a volume, usually one of several. There are several types of vacuum pumps, such as root pumps, diaphragm pumps, rotary piston pumps, and self-priming centrifugal pumps.

The diaphragm pump is a dry positive displacement vacuum pump

Diaphragm pumps are a versatile type of vacuum pump. They can be installed in a variety of scenarios including container emptying, positive suction, and simultaneous fluid mixing. Their performance depends on the stiffness and durability of the diaphragm, which in turn depends on the material.

They have good performance when running in dry mode. Diaphragm pumps work very similarly to the human heart, which is why they are often used to create artificial hearts. In addition, the diaphragm pump is self-priming and has high efficiency. They are also capable of handling the most viscous liquids and are used in almost all industries.

However, this type of pump has several disadvantages. One of them is that they are difficult to restart after a power outage. Another disadvantage is that they can generate a lot of heat. Fortunately, this heat is carried away by airflow. However, this heat builds up in the multistage pump. If this happens, the diaphragm or motor may be damaged. Diaphragm pumps operating in two or more stages should be fitted with solenoid valves to maintain vacuum stability.

Diaphragm pumps are a good choice for drying processes where hygiene is important. These pumps have check valves and rubber or Teflon diaphragms. Diaphragm pumps are also ideal for high viscosity applications where shear sensitivity is important.

Roots pumps are dry method centrifugal pumps

Roots pumps use a vane rotor pump with two counter-rotating vanes that move in opposite directions to move the gas. They are often the first choice for high-throughput process applications. Depending on the size and number of blades, they can withstand up to 10 Torr.

Centrifugal pumps have several advantages, including the ability to handle corrosive fluids and high temperatures. However, when choosing a pump, it is essential to choose a reputable manufacturer. These companies will be able to advise you on the best pump design for your needs and provide excellent after-sales support. Roots pumps can be used in a wide range of industrial applications including chemical, food, and biotechnology.

The Roots pump is a dry centrifugal pump whose geometry enables it to achieve high compression ratios. The screw rotors are synchronized by a set of timing gears that allow gas to pass in both directions and create a compressed state in the chamber. The pre-compressed gas is discharged through a pressure connection and cooled with water. Some pumps are also able to accept additional cooling gas, but this should be done with caution.

The size of the impeller plays an important role in determining the pump head. The impeller diameter determines how high the pump can lift the liquid. Impeller speed also affects the head. Since the head is proportional to the specific gravity of the liquid, the available suction pressure will be proportional to the density of the liquid. The density of water is about 1.2 kg/m3, and the suction pressure of the centrifugal pump is not enough to lift the water.

The rotary vane pump is a self-priming centrifugal pump

A rotary vane pump is a centrifugal pump with a circular pump head and a cycloid cam that supports the rotor. The rotor is close to the cam wall, and two side plates seal the rotor. Vanes in vane pumps are installed in these cavities, and the rotor rotates at high speed, pushing fluid in and out of the pump. The pump offers several advantages, including a reversible design and the ability to handle a wide variety of clean fluids.

Agknx Pumps manufactures a wide range of vane pumps that combine high performance, low cost, and easy maintenance. These pumps handle medium to high viscosity liquids up to 500 degrees Fahrenheit and 200,000 SSU.

The suction side of the rotary vane pump has a discharge port, and the valve prevents the backflow of the discharge air. When the maximum pressure is reached, the outlet valve closes to prevent the backflow of exhaust gas. The mechanical separation step separates the oil from the gas in the pump circuit and returns the remaining oil particles to the sump. The float valve then reintroduces these oil particles into the oil circuit of the pump. The gas produced is almost oil-free and can be blown out of a pipe or hose.

Rotary vane pumps are self-priming positive displacement pumps commonly used in hydraulic, aeration, and vacuum systems. Unlike gear pumps, rotary vane pumps can maintain high-pressure levels while using relatively low suction pressures. The pump is also very effective when pumping viscous or high-viscosity liquids.

Rotary piston pumps are dry method positive displacement pumps

Rotary piston pumps are dry positive displacement pumps designed to deliver high-viscosity fluids. They are capable of pumping a variety of liquids and can run dry without damaging the liquid. Rotary piston pumps are available in a variety of designs. Some are single shafts, some are two shafts and four bearings.

Positive displacement pumps operate slower than centrifugal pumps. This feature makes the positive displacement pump more sensitive to wear. Piston and plunger reciprocating pumps are particularly prone to wear. For more demanding applications, progressive cavity, diaphragm or lobe pumps may be a better choice.

Positive displacement pumps are typically used to pump high-viscosity fluids. This is because the pump relies on a mechanical seal between the rotating elements and the pump casing. As a result, when fluids have low viscosity, their performance is limited. Additionally, low viscosity fluids can cause valve slippage.

These pumps have a piston/plunger arrangement using stainless steel rotors. Piston/piston pumps have two cavities on the suction side. The fluid then flows from one chamber to the other through a helical motion. This results in very low shear and pulsation rates. The pump is usually installed in a cylindrical housing.

Rotary vane pump corrosion resistance

Rotary vane vacuum pumps are designed for use in a variety of industries. They feature plasma-treated corrosion-resistant parts and anti-suck-back valves to help reduce the number of corrosive vapors entering the pump. These pumps are commonly used in freeze dryers, vacuum ovens, and degassing processes. The high flow rates they provide in their working vacuum allow them to speed up processes and reduce the time it takes to run them. Plus, they have energy-efficient motors and silent volume. <br/While rotary vane vacuum pumps are relatively corrosion resistant, they should not be used for aggressive chemicals. For these chemicals, the most suitable pump is the chemical mixing pump, which combines two types of pumps to improve corrosion resistance. If the application requires a more powerful pump, a progressive cavity pump (eg VACUU*PURE 10C) is suitable.

Oil seals used in rotary vane pumps are important to pump performance. The oil seal prevents corrosion of the aluminum parts of the rotary vane pump and prolongs the service life. Most rotary vane vacuum pumps have a standard set of components, although each component may have different oil seals.

Rotary vane vacuum pumps are the most common type of positive displacement pump. They provide quiet operation and long service life. They are also reliable and inexpensive and can be used in a variety of applications.

Roots pumps are primarily used as a vacuum booster

Root vacuum pumps are mainly used as vacuum boosters in industrial applications. They need a thorough understanding of operating principles and proper maintenance to function properly. This course is an introduction to Roots vacuum pumps, covering topics such as pump principles, multi-stage pumps, temperature effects, gas cooling, and maintenance.

Roots pumps have many advantages, including compact and quiet operation. They do not generate particles and have a long service life. They also don’t require oil and have a small footprint. However, Roots pumps have several disadvantages, including relatively high maintenance costs and low pumping speeds near atmospheric pressure.

Root vacuum pumps are often used with rotary vane vacuum pumps. They work on the same principle, the air enters a conveying unit formed by two rolling pistons in the housing. The piston heads are separated from each other, and the air passes through the unit without being reduced until it is discharged. When the air in the next unit reaches a higher absolute pressure, it is expelled from the last unit.

Roots pumps can be classified as sheathed or sealed. Roots pumps with sealed motors are suitable for pumping toxic gases. They have less clearance between the stator and motor rotor and have a sealed tank.

editor by CX 2023-05-26

China Hot selling Oilgear Hydraulic Pump Variable Plunger Pvm-130/75/2564-A2ub-Rsfy-P-1nnsn Gear Pump/High Pressure Pump/Vacuum Pump supplier

Product Description

American OILGEAR plunger pump PFCS series PVV series PVK series PVG series PVW series PVM series

PVM hydraulic pump – high performance open axial piston pump

PVWH hydraulic pump – low horsepower high performance open axial piston pump

PVWW hydraulic pump – low horsepower high performance open axial piston pump for low viscosity or water-containing oil

PVWC hydraulic pump-low horsepower high performance closed axial piston pump

PVG hydraulic pump – mid-range horsepower high performance open axial piston pump

PVK hydraulic pump-mid-range-high-end horsepower high-performance open axial piston pump

PVV hydraulic pump – high horsepower high performance open axial piston pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFCM hydraulic pump – high pressure and high load open multi-stage quantitative output pump

PFCS hydraulic pump – high pressure and high load open multi-stage quantitative output pump

DN type hydraulic pump-variable radial piston pump

PVG-048-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LSFY-P-1NNSN

PVG-075-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-RDFZ-P-1NNSN-CN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-RGFK-P-1NN/H100SN-NN

PVG-130-F1UV-RDFZ-P-1NNNN

PVG-130-F1UV-LDFY-P-1NN/H050NN-CP

PVG-100-F1UV-LDFY-P-1NNSN-CP

PVG-100-FIUV-LGFZ-P-1NNSN-NN

PVG-048-F1UV-LGFY-N-1NNNN-AA/05

PVG-100-F1UV-LGFY-N-20RSA

PVG-075-F1UV-LSFY-P-1NNSN-NN

PVG-075-F1UV-RDFY-N-1NNNN-AA/05

PVG-065-F1UB-RGFY-P-1NNNN-NN

PVG-065-F1UP-RGFY-P-1NNNN-NN (Test Equipment)

PVG-065-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-RGFK-P-1NN/G047SN/827

PVG-100-FIUV-LGFZ-P-1NNSN

PVG-130-E1UB-LSFY-P-1NNSN/704 (PVG-130-F1UB-LSFY-P-1NNSN/844)

PVG-130-F1UB-LSFY-P-1NNSN/844

PVG-130-F1UB-RSFY-P-1NNSN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-LGFK-P-1NN/FNN-NN

PVG-150-A1UV-LGFY-P-1NNNN

PVK-140-A1UV-RDFS-P-1NNSN-CP/133 for Komatsu

PVK-270-B1UV-RDFY-P-1NNSN-CP

PVM-011-BIUB-RSAY-P-1NNNN

PVM-046-A1UB-RSFY-P-1NNNN

PVM-130-A2UV-RSFY-P-1NNSN

PVM-130-A2UV-RSFY-P-1NNSN (for thin oil stations on chemical plants)

PVV-250-B1BV-RSFY-P-1NNSN-NN

PVV-250-B1UV-RSFY-F-100SB

PVWH-06-LSAY-MNSA

Upgrade (PVWJ-014-A1UV-LSAY-M-NNSA)

PVWH-11-LDFS-CFNN-THCPP17571C

PVWJ-011-A1UV-RSAY-P-1NNSN

PVL Hydraulic Pump-Variable Axial Piston Pump

FCS Hydraulic Pump – Swing Plate Driven Inspection Valve Type Grading Quantitative PumpAmerican OILGEAR plunger pump PFCS series PVV series PVK series PVG series PVW series PVM series

PVM hydraulic pump – high performance open axial piston pump

PVWH hydraulic pump – low horsepower high performance open axial piston pump

PVWW hydraulic pump – low horsepower high performance open axial piston pump for low viscosity or water-containing oil

PVWC hydraulic pump-low horsepower high performance closed axial piston pump

PVG hydraulic pump – mid-range horsepower high performance open axial piston pump

PVK hydraulic pump-mid-range-high-end horsepower high-performance open axial piston pump

PVV hydraulic pump – high horsepower high performance open axial piston pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFBA hydraulic pump – high horsepower and high load open multi-stage quantitative output pump

PFCM hydraulic pump – high pressure and high load open multi-stage quantitative output pump

PFCS hydraulic pump – high pressure and high load open multi-stage quantitative output pump

DN type hydraulic pump-variable radial piston pump

PVG-048-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LDFY-P-1NNSN

PVG-065-F1UV-LSFY-P-1NNSN

PVG-075-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-LSFY-P-1NNSN

PVG-130-F1UV-RDFZ-P-1NNSN-CN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-RGFK-P-1NN/H100SN-NN

PVG-130-F1UV-RDFZ-P-1NNNN

PVG-130-F1UV-LDFY-P-1NN/H050NN-CP

PVG-100-F1UV-LDFY-P-1NNSN-CP

PVG-100-FIUV-LGFZ-P-1NNSN-NN

PVG-048-F1UV-LGFY-N-1NNNN-AA/05

PVG-100-F1UV-LGFY-N-20RSA

PVG-075-F1UV-LSFY-P-1NNSN-NN

PVG-075-F1UV-RDFY-N-1NNNN-AA/05

PVG-065-F1UB-RGFY-P-1NNNN-NN

PVG-065-F1UP-RGFY-P-1NNNN-NN (Test Equipment)

PVG-065-F1UV-LSFY-P-1NNSN

PVG-100-F1UV-RGFK-P-1NN/G047SN/827

PVG-100-FIUV-LGFZ-P-1NNSN

PVG-130-E1UB-LSFY-P-1NNSN/704 (PVG-130-F1UB-LSFY-P-1NNSN/844)

PVG-130-F1UB-LSFY-P-1NNSN/844

PVG-130-F1UB-RSFY-P-1NNSN

PVG-130-F1UV-LGFK-P-1NN/FNN

PVG-130-F1UV-LGFK-P-1NN/FNN-NN

PVG-150-A1UV-LGFY-P-1NNNN

PVK-140-A1UV-RDFS-P-1NNSN-CP/133 for Komatsu

PVK-270-B1UV-RDFY-P-1NNSN-CP

PVM-011-BIUB-RSAY-P-1NNNN

PVM-046-A1UB-RSFY-P-1NNNN

PVM-130-A2UV-RSFY-P-1NNSN

PVM-130-A2UV-RSFY-P-1NNSN (for thin oil stations on chemical plants)

PVV-250-B1BV-RSFY-P-1NNSN-NN

PVV-250-B1UV-RSFY-F-100SB

PVWH-06-LSAY-MNSA

Upgrade (PVWJ-014-A1UV-LSAY-M-NNSA)

PVWH-11-LDFS-CFNN-THCPP17571C

PVWJ-011-A1UV-RSAY-P-1NNSN

PVL Hydraulic Pump-Variable Axial Piston Pump

FCS Hydraulic Pump – Swing Plate Driven Inspection Valve Type Grading Quantitative Pump

| Type: | Gear Pump |

|---|---|

| Transport Package: | Standard Wooden Box or Carton |

| Specification: | 35*35*40 |

| Origin: | USA |

| Customization: |

Available

|

|

|---|

How to install a vacuum pump

A vacuum pump creates a relative vacuum within a sealed volume by drawing gas molecules from the sealed volume. Vacuum pumps can be used in a variety of industrial applications. They also offer various lubrication options. If you are considering purchasing, please understand its functions and features before purchasing.

How it works

The working principle of a vacuum pump is called gas transfer. The principle can be further divided into two basic categories: positive displacement and momentum transfer. At high pressure and moderate vacuum, gas molecules collide and move and create a viscous flow. At higher vacuum levels, gas molecules separate to create molecular or transitional flows.

Another principle of vacuum pumps is fluid-tightness. There are two main types of seals: rotary seals and screw seals. Rotary seals prevent liquid leakage, while screw seals only allow liquids to flow out at higher pressures. Some pumps may not use the third seal.

The flow rate of the vacuum pump determines the machine’s ability to pump a certain amount of material. A higher pumping speed will shorten the drain time. Therefore, the mass flow of the vacuum pump must be carefully considered. The speed and type of vacuum must also be considered.

The working principle of a vacuum pump is to push gas molecules from a high-pressure state to a low-pressure state. This creates a partial vacuum. There are many different types of vacuum pumps, each with different functions. Some are mechanical, some are chemical. In either case, their function is the same: to create a partial or complete vacuum. Vacuum pumps use a variety of technologies and are sized according to the application. Proper sizing is critical for optimum efficiency.

Gas transfer pumps use the same principles as vacuum pumps but use different technology. One of the earliest examples is the Archimedes spiral. Its structure consists of a single screw inside a hollow cylinder. More modern designs use double or triple screws. The rotation of the screw causes gas molecules to be trapped in the cavity between the screw and the housing. The fluid is then discharged at slightly above atmospheric pressure. This difference is called the compression ratio.

Another type of vacuum pump is a diffusion pump. Its main use is industrial vacuum processing. It is used in applications such as mass spectrometry, nanotechnology and analytical instrumentation. These pumps are generally inexpensive to purchase and operate.

Apply

Vacuum pumps are essential for many scientific and industrial processes. They are used in the production of vacuum tubes, CRTs, lamps and semiconductor processing. They can also be used to support mechanical equipment. For example, they can be mounted on the engine of a motor vehicle. Likewise, they can be used to power hydraulic components of aircraft. Among other uses, the vacuum pump helps calibrate the gyroscope.

Vacuum pumps are widely used in the pharmaceutical industry and are one of the largest users of this technology. They help deal with hazardous materials and eliminate waste quickly. They are also used in power jets, dump fuel tanks and rear doors, among others. However, they are sensitive to contamination and should only be used in environments where leaks can be prevented. Therefore, choosing the right fluid for the application is very important.

The most popular type of vacuum pump is the rotary vane pump. These pumps are known for their high pumping speed and low pressure. Their efficient pumping capacity allows them to reach pressures below 10-6 bar. Additionally, they are usually oil-sealed and have excellent vacuuming capabilities.

Vacuum pumps are often used to remove air from closed systems. They create a vacuum by reducing the density of the air in the compressed space. This is done by using the mechanical force energy generated by the rotating shaft. When the pump is under pressure, it converts this energy into pneumatic power. When the pressure is different, the energy produced depends on the volume of the gas and the pressure difference between the inner and outer atmospheres.

Vacuum pumps are also used in the manufacture of solar cells. They are used in the manufacture of solar cells, including ingot casting processes as well as cell and module processes. The design of the vacuum system plays an important role in reducing the cost of the process, thus making it profitable. Due to their low maintenance costs, they are an invaluable tool for making solar cells.

Vacuum pumps are widely used in many applications. In addition to industrial and research uses, they are also used in water remediation.

Oil Lubrication Option

Vacuum pumps are available in a variety of oil lubrication options. Choosing the right lubricant can help protect your vacuum pump and maximize its performance. Different base oils may contain different additives, such as antioxidants, and some contain additional additives for specific purposes. You should choose an oil with the right concentration of these additives for optimal lubrication of your vacuum pump.

Vacuum pumps are usually lubricated with paraffinic mineral oil. However, this type of lubricant evaporates as the temperature increases. To minimize evaporative losses, choose a lubricant with low vapor pressure. Also, you should choose lubricants that are resistant to extreme temperatures. Extreme temperatures can put extra stress on the oil and can even significantly shorten the life of the oil.