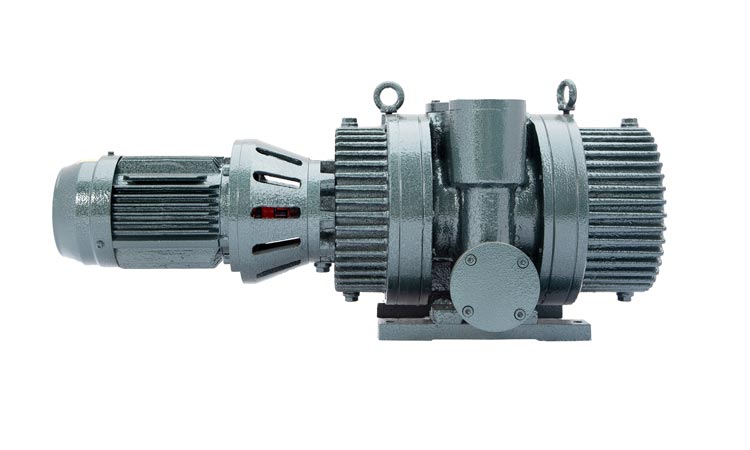

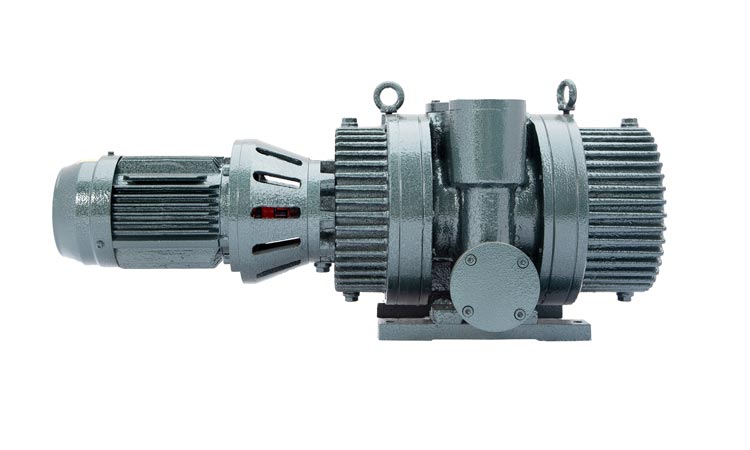

Product Description

Vacuum pump is used in the field of chemical and pharmaceutical factory

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

New plant plHangZhou

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

High precision machining equipment

The company cooperates with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents. Adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

Product quality wins consumer cooperationIn shipment

ISO 9001

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifetime Paid Service |

|---|---|

| Warranty: | One Year |

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

How Do Roots Vacuum Pumps Affect the Efficiency of Vacuum Systems in Various Industries?

Roots vacuum pumps have a significant impact on the efficiency of vacuum systems across various industries. Here’s a detailed explanation:

1. Enhanced Vacuum Level:

– High Pumping Speed: Roots vacuum pumps are known for their high pumping speed, which refers to the rate at which they can evacuate gas from a system. By quickly removing gas molecules, these pumps help achieve and maintain a lower pressure, resulting in an enhanced vacuum level within the system. This increased vacuum level is crucial in industries such as semiconductor manufacturing, where precise control of pressure is necessary for optimal processing conditions.

– Improved Evacuation Time: With their rapid gas pumping capability, Roots vacuum pumps significantly reduce the evacuation time required to reach the desired vacuum level. This efficiency is particularly important in industries where time-sensitive processes are involved, such as vacuum drying, degassing, or impregnation, allowing for faster production cycles and increased productivity.

2. Increased Throughput:

– Continuous Operation: Roots vacuum pumps are designed for continuous operation, enabling uninterrupted gas removal from the vacuum system. Their robust construction and oil-free operation make them reliable and suitable for demanding industrial applications. The ability to maintain a consistent vacuum level without frequent stops or downtime contributes to increased system throughput and overall efficiency.

– Handling Large Volumes: Roots pumps are capable of handling large gas volumes due to their displacement principle. This makes them well-suited for industries that require the evacuation of substantial amounts of gas, such as in chemical processing, pharmaceutical manufacturing, or vacuum packaging. By efficiently evacuating large volumes of gas, Roots vacuum pumps facilitate higher production rates and improved process efficiency.

3. Improved Process Control:

– Stable Vacuum Level: Roots vacuum pumps help maintain a stable vacuum level within the system, which is essential for precise process control. By swiftly removing gas molecules, these pumps prevent pressure fluctuations and ensure a consistent environment for various manufacturing processes. This is particularly crucial in industries like thin film deposition, where maintaining a stable vacuum is crucial for achieving uniform coating thickness and quality.

– Reduced Contamination: Roots vacuum pumps operate without lubricating oil in the pumping chamber, minimizing the risk of oil contamination in the vacuum system. This is particularly advantageous in industries such as electronics, semiconductor fabrication, or research laboratories, where even trace amounts of contaminants can adversely affect product quality or experimental results. By providing clean and oil-free vacuum, Roots pumps contribute to improved process control, reduced yield loss, and enhanced product reliability.

4. Energy Efficiency:

– Lower Power Consumption: Roots vacuum pumps are designed to operate efficiently, consuming lower power compared to other types of vacuum pumps. This energy efficiency is beneficial in industries where vacuum systems are continuously operated, such as in chemical processing plants or industrial manufacturing facilities. By reducing power consumption, Roots pumps help lower operational costs and contribute to sustainable and environmentally friendly practices.

– Heat Dissipation: Roots pumps generate less heat during operation compared to certain other vacuum pump types. This is advantageous in industries where temperature control is critical, such as in semiconductor fabrication or vacuum furnaces. The reduced heat generation minimizes the need for additional cooling measures, improving overall energy efficiency and reducing operational costs.

In summary, Roots vacuum pumps significantly impact the efficiency of vacuum systems in various industries. They enhance the vacuum level, increase system throughput, improve process control, and contribute to energy savings. By providing high pumping speed, quick evacuation time, continuous operation, stable vacuum levels, reduced contamination risk, lower power consumption, and efficient heat dissipation, Roots vacuum pumps play a crucial role in optimizing the performance and productivity of vacuum systems across industries.

Can Roots Vacuum Pumps Be Used for Vacuum Distillation?

Yes, Roots vacuum pumps can be used for vacuum distillation in certain applications. Here’s a detailed explanation:

Vacuum distillation is a process used to separate and purify components of a liquid mixture by exploiting the difference in boiling points under reduced pressure. By operating at lower pressures, the boiling points of the components are decreased, allowing for more selective evaporation and separation. Vacuum distillation is commonly employed in industries such as petrochemical, pharmaceutical, and chemical manufacturing.

Roots vacuum pumps can play a role in vacuum distillation processes by assisting in the creation and maintenance of the required vacuum conditions. Although Roots vacuum pumps alone may not achieve the high vacuum levels necessary for certain applications, they are often used in combination with other vacuum pumps, such as rotary vane pumps or oil-sealed pumps, to create a hybrid pumping system.

In a typical setup, Roots vacuum pumps are utilized as the primary roughing pump in the distillation system. Their high pumping speed allows for efficient removal of large volumes of gas, reducing the pressure in the system and enabling the effective operation of subsequent stages. The Roots pump works by trapping and compressing the gas, creating a pressure differential that facilitates the evacuation of the system.

While Roots vacuum pumps are effective in generating rough vacuum levels, they may not be capable of achieving the very high vacuum levels often required for precise separation in vacuum distillation. Therefore, they are commonly used in conjunction with other vacuum pumps, such as oil-sealed pumps or molecular pumps, that are better suited for achieving and maintaining high vacuum levels.

It’s important to note that the selection and configuration of the vacuum pumps for vacuum distillation depend on various factors, including the desired vacuum level, the characteristics of the liquid mixture being distilled, and the specific requirements of the distillation process. The vacuum system needs to be carefully designed to ensure optimal performance and efficient separation.

In summary, while Roots vacuum pumps alone may not be sufficient for achieving the high vacuum levels required for vacuum distillation, they are commonly employed as part of a hybrid pumping system in conjunction with other vacuum pumps. Their high pumping speed and capability to handle large gas volumes make them valuable for creating the initial vacuum conditions in the distillation process.

editor by Dream 2024-05-10

China Standard Vakuum Pumpe Air Rotary Roots Liquid-Ring Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps vacuum pump for ac

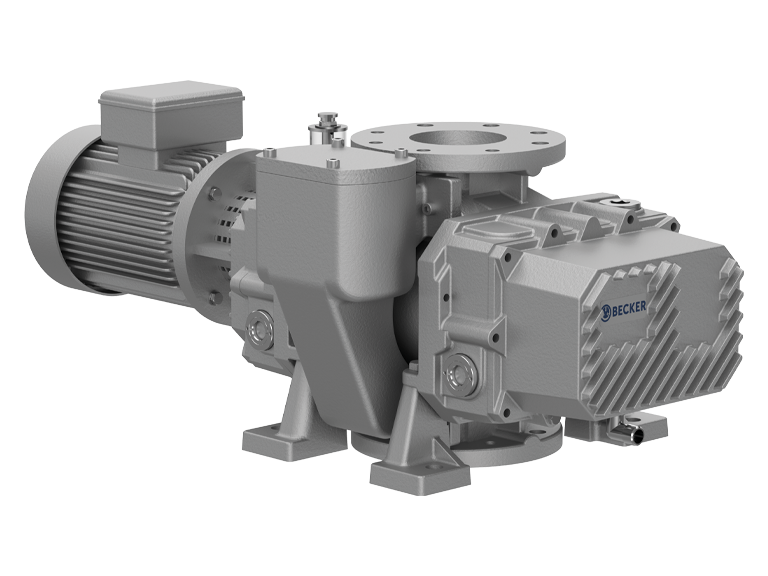

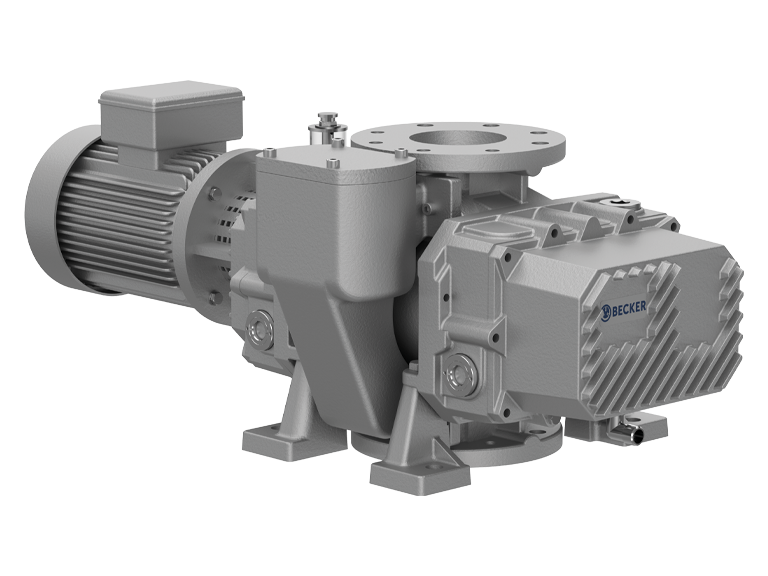

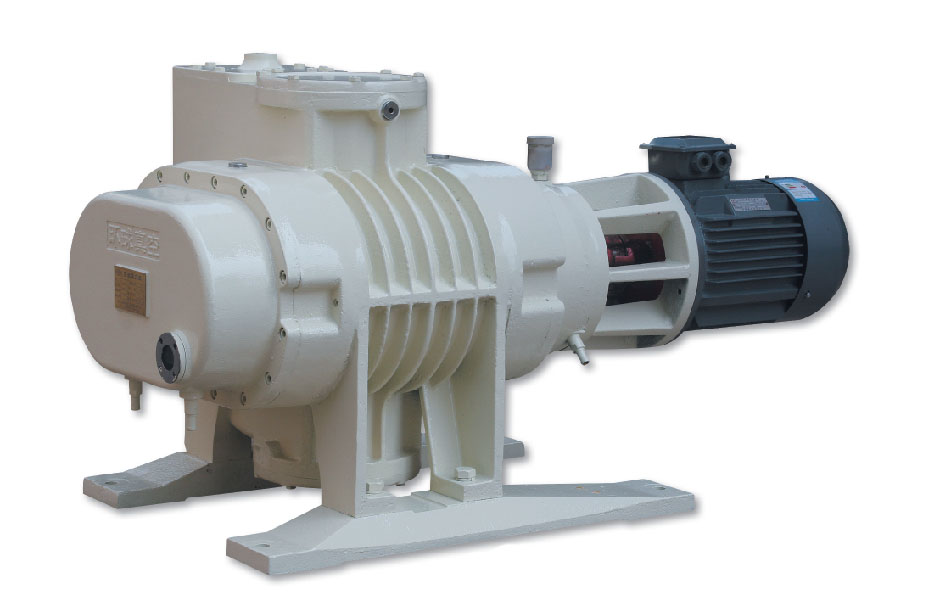

Product Description

Vakuum Pumpe Air Rotary Roots Liquid-Ring Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps

VP roots vacuum pump is in the 50 Torr-micron high vacuum range has a large pumping speed and low cost of equipment, it can be combined with various vacuum pump consists of a vacuum unit. KMBD roots vacuum pump with 5 point bearing design unique, sealing the five bit machine, sealing double sealing structure + mechanical seal for Teflon maze, can realize non leakage, reduce maintenance and repair of the link, ensure the roots pump and durable. Synchronous helical gear and mounted on the driving end, both to ensure quiet and reliable operation, and can reduce the load of the rotor torque. Impeller and shaft integrally cast, can provide large size shaft, impeller and reduce the risk of damage. All contact with the sealing surface of the shaft end faces are polished to reduce wear and reduce the risk of leakage, high temperature high pressure casing, and double tank design, a variety of material selection, further to ensure that the use of the user in various working conditions. Typical application: chemical, petrochemical, plastics, semiconductors, wood mixture, food processing, vacuum furnace, vacuum booster system, vacuum drying, vacuum dewatering, vacuum packaging

Typical Applications

Special structures working principles,suitable for operation in chemical industry,oil industry,food industry,electrical utility industry,pharmacy industry,textile industry and paper making industry,etc. The other industries that need vacuum drying,concentration,distilling,dehydration and filtering also need the water-ring vacuum pump. It can be use as a backing pump of Roots Pump.

Specifications

| Model | Capacity | Ultimate Pressure | Power | speed |

| L/S | Pa | KW | RPM | |

| VP200 | 200 | 0.05 | 4 | 2900 |

| VP600 | 600 | 0.05 | 7.5 | 2900 |

Characteristic Curves

Overall Dimensions

company information

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Optional |

|---|---|

| Inlet Diam. (mm): | 100/200mm |

| Motor Power (Kw): | 4/7.5 Kw |

| Ultimate Pressure (PA): | 0.05 |

| Transport Package: | Wooden Case |

| Trademark: | OEM |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

How Are Roots Vacuum Pumps Utilized in the Automotive Industry?

Roots vacuum pumps play a significant role in various applications within the automotive industry. Here’s a detailed explanation:

1. Brake System Vacuum Pumps:

– Vacuum Boosters: Roots vacuum pumps are commonly used as vacuum boosters in automotive brake systems. They assist in enhancing the braking performance by providing the necessary vacuum for power brake operation. When the driver applies the brake pedal, the vacuum booster uses the suction power generated by the Roots pump to amplify the force applied to the brake master cylinder, resulting in more effective braking.

– Electric Brake Vacuum Pumps: In modern electric or hybrid vehicles, where traditional engine-driven vacuum sources may not be available, electric brake vacuum pumps are utilized. These pumps, often based on the Roots principle, generate vacuum independently to power the brake booster and ensure reliable braking performance.

2. Emissions Control:

– Evaporative Emission Control: Roots vacuum pumps are employed in evaporative emission control systems to prevent the release of harmful vapors from the fuel system into the atmosphere. These pumps create a vacuum within the system, purging and storing fuel vapors in a canister for subsequent combustion or recycling.

– Positive Crankcase Ventilation (PCV): PCV systems, which are designed to reduce emissions and maintain the integrity of the engine, also utilize Roots vacuum pumps. These pumps draw crankcase gases and vapors, including oil mist, from the engine’s crankcase into the intake manifold for combustion, improving overall engine efficiency and reducing pollution.

3. Engine Testing and Development:

– Vacuum Leakage Testing: Roots vacuum pumps are utilized for vacuum leakage testing in engine manufacturing and development. By creating a vacuum in the intake manifold or other engine components, these pumps enable the detection of leaks and ensure the integrity of the engine’s air delivery system.

– Air Flow Calibration: During engine testing and calibration, Roots vacuum pumps are used to simulate various operating conditions by controlling the intake air flow. This allows engineers to fine-tune the engine’s performance, optimize fuel-air mixture ratios, and assess the engine’s efficiency and emissions characteristics.

4. HVAC Systems:

– Climate Control: Roots vacuum pumps are employed in automotive HVAC (Heating, Ventilation, and Air Conditioning) systems to facilitate the flow and distribution of air. These pumps help regulate the operation of HVAC components, such as air blend doors and vacuum actuators, ensuring proper air temperature and direction control inside the vehicle cabin.

5. Fuel System and Turbocharging:

– Fuel Transfer and Evacuation: In automotive fuel systems, Roots vacuum pumps are used for fuel transfer and evacuation. These pumps assist in priming the fuel system, removing air pockets, and ensuring the continuous flow of fuel to the engine, enhancing the overall fuel delivery performance.

– Turbocharger Control: Roots vacuum pumps are sometimes employed in turbocharged engines to control the actuation of variable geometry turbochargers (VGT). These pumps provide the necessary vacuum signals to actuate the VGT mechanism, optimizing turbocharger performance and enhancing engine efficiency.

6. Other Applications:

– Electric Vehicle Battery Systems: In electric vehicles, Roots vacuum pumps are utilized to create a vacuum in battery enclosures, helping to maintain the integrity and safety of the battery system by preventing the ingress of moisture, dust, or contaminants.

– Engine Air Induction: Some automotive engines utilize Roots-type superchargers or twin-screw superchargers, which are essentially positive displacement Roots vacuum pumps operating in reverse. These devices compress and force air into the engine’s intake manifold, resulting in increased engine power and performance.

In summary, Roots vacuum pumps find extensive utilization in the automotive industry. They play a crucial role in brake systems, emissions control, engine testing and development, HVAC systems, fuel systems, turbocharging, electric vehicle battery systems, and engine air induction. By contributing to braking performance, emissions reduction, engine calibration, HVAC functionality, fuel system efficiency, turbocharger control, battery system safety, and engine power enhancement, Roots vacuum pumps contribute significantly to the overall operation and performance of automotive systems and components.

What Are the Advantages of Using Roots Vacuum Pumps?

Roots vacuum pumps, also known as Roots blowers or rotary lobe pumps, offer several advantages that make them a popular choice for various industrial applications. Here’s a detailed explanation of the advantages of using Roots vacuum pumps:

1. High Pumping Speed: Roots vacuum pumps are known for their high pumping speed, which refers to the rate at which they can remove gas from a vacuum system. The unique design of synchronized rotating lobes enables these pumps to handle large volumes of gas efficiently. This high pumping speed makes Roots vacuum pumps well-suited for applications that require rapid evacuation or continuous extraction of gases.

2. Large Gas Handling Capacity: Roots vacuum pumps have a large gas handling capacity, allowing them to handle a wide range of gases, including clean air, corrosive gases, and vapors. Their robust construction and ability to handle gas with particulates or liquids make them suitable for applications in industries such as chemical processing, pharmaceuticals, food processing, and wastewater treatment.

3. Oil-Free and Contamination-Free Operation: One of the significant advantages of Roots vacuum pumps is that they operate without the need for lubrication. The non-contacting design of the pump eliminates the risk of oil contamination in the vacuum system. This is particularly important in applications where clean, oil-free vacuum environments are required, such as semiconductor manufacturing, electronics, and research laboratories.

4. Reliable and Low Maintenance: Roots vacuum pumps are known for their reliability and low maintenance requirements. Since there is no lubrication or contact between the lobes, there is minimal wear and tear, reducing the need for frequent maintenance or replacement of parts. This results in reduced downtime and lower operating costs for the users.

5. Noise and Vibration Reduction: Roots vacuum pumps are designed to operate with low noise and vibration levels. The precision engineering and balanced rotation of the lobes help minimize noise generation and vibration transmission. This makes Roots vacuum pumps suitable for applications where noise reduction and vibration control are important, such as in laboratories, medical facilities, and residential areas.

6. Wide Range of Vacuum Levels: While Roots vacuum pumps are not capable of achieving high vacuum levels on their own, they can be combined with other vacuum pumps, such as rotary vane pumps or diffusion pumps, to create hybrid or combination pumping systems. This allows them to cover a wide range of vacuum levels, making them versatile and adaptable to different application requirements.

7. Energy Efficiency: Roots vacuum pumps are designed to be energy-efficient, offering a favorable power-to-pumping speed ratio. Their efficient design and minimal internal losses help reduce energy consumption, resulting in lower operating costs for the users. This makes them an economical choice for continuous or high-throughput processes that require significant vacuum power.

8. Versatility and Compatibility: Roots vacuum pumps are compatible with various gases and can be used in a wide range of industrial applications. They find applications in industries such as chemical processing, pharmaceuticals, food processing, automotive, packaging, and environmental technology. Their versatility and compatibility make them suitable for both rough vacuum applications and as part of complex vacuum systems.

In summary, the advantages of using Roots vacuum pumps include high pumping speed, large gas handling capacity, oil-free and contamination-free operation, reliability, low maintenance requirements, noise and vibration reduction, a wide range of vacuum levels, energy efficiency, versatility, and compatibility. These advantages make Roots vacuum pumps a preferred choice for many industrial processes that require efficient and reliable vacuum generation.

editor by Dream 2024-04-22

China wholesaler Roots Liquid-Ring Water Piston Rotary Vane Dry Portable Screw Scroll Reciprocating Diaphragm Positive Displacement Industrial Air Small Centrifugal Vacuum Pump vacuum pump and compressor

Product Description

Roots Liquid-ring water piston Rotary vane Dry portable Screw scroll Reciprocating diaphragm positive displacement industrial air small centrifugal vacuum pump

Application of vacuum pump

Vacuum pumps are used in a wide variety of applications, including:

- Industrial: Vacuum pumps are used in a variety of industrial applications, such as food processing, material handling, and packaging.

- Scientific: Vacuum pumps are used in a variety of scientific applications, such as electron microscopy, mass spectrometry, and vacuum chambers.

- Medical: Vacuum pumps are used in a variety of medical applications, such as surgery, wound care, and blood collection.

- Domestic: Vacuum pumps are used in a variety of domestic applications, such as vacuum cleaners, food dehydrators, and wine preservation systems.

Vacuum pumps work by removing air and other gases from a chamber. This can be done in a variety of ways, but the most common method is to use a rotating impeller that creates a vacuum.

The benefits of using a vacuum pump include:

- Reduced pressure: Vacuum pumps can reduce the pressure in a chamber, which can be useful for a variety of applications.

- Improved air quality: Vacuum pumps can remove dust, dirt, and other particles from the air, which can improve air quality.

- Increased efficiency: Vacuum pumps can improve the efficiency of a variety of processes, such as food processing and material handling.

- Reduced costs: Vacuum pumps can reduce the costs of a variety of processes, such as food processing and material handling.

The disadvantages of using a vacuum pump include:

- Noise: Vacuum pumps can be noisy, especially at high speeds.

- Vibration: Vacuum pumps can vibrate, especially at high speeds.

- Cost: Vacuum pumps can be expensive, especially for large and high-powered models.

Overall, vacuum pumps are a versatile and reliable component that can be used in a wide variety of applications. They offer a number of advantages, including reduced pressure, improved air quality, increased efficiency, and reduced costs. However, they also have some disadvantages, such as noise and vibration.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide 1-Year Warranty |

|---|---|

| Warranty: | Installation Guide 1-Year Warranty |

| Oil or Not: | Oil |

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | Vacuum |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can Roots Vacuum Pumps Be Used for Vacuum Impregnation in Manufacturing?

Yes, Roots vacuum pumps can be used for vacuum impregnation in manufacturing. Here’s a detailed explanation:

1. Vacuum Impregnation in Manufacturing: Vacuum impregnation is a process used in manufacturing to fill porous materials or components with a liquid or resin. It is commonly employed to enhance the properties of materials by improving their strength, sealing capability, or resistance to chemicals or corrosion. The process involves placing the porous material in a vacuum chamber and removing the air or gas trapped within its pores. Once a vacuum is established, a liquid or resin is introduced, and the vacuum is released, allowing the material to absorb the impregnating substance.

2. Role of Roots Vacuum Pumps: Roots vacuum pumps play a crucial role in the vacuum impregnation process by creating and maintaining the required vacuum conditions. Here’s how they contribute:

– Evacuation: Roots pumps are used to evacuate the impregnation chamber, removing the air and gas from within the pores of the porous material. By creating a vacuum, the trapped gases are extracted, creating a void space for the impregnating substance to penetrate.

– Pressure Control: Roots pumps help control the pressure within the impregnation chamber during different stages of the process. They can rapidly achieve and maintain the desired vacuum level, ensuring proper impregnation of the material and preventing the formation of air bubbles or voids.

– Gas Removal: Roots pumps effectively remove gases released from the impregnating substance during the impregnation process. As the liquid or resin fills the pores of the porous material, gases may be released due to the reaction or outgassing. The vacuum pump evacuates these gases, preventing their accumulation and ensuring complete impregnation.

3. Advantages of Roots Vacuum Pumps for Vacuum Impregnation:

– High Pumping Speed: Roots vacuum pumps have a high pumping speed, enabling rapid evacuation of the impregnation chamber. This reduces the overall impregnation cycle time, increasing manufacturing throughput and efficiency.

– Large Volume Handling: Roots pumps are capable of handling large volumes of gas, allowing them to evacuate chambers of different sizes effectively. This is advantageous when impregnating large or complex-shaped components that require a significant amount of impregnating substance.

– Continuous Operation: Roots pumps can operate continuously, maintaining the vacuum conditions required for impregnation throughout the process. This ensures consistent impregnation results and reduces the risk of incomplete impregnation or material defects.

– Compatibility with Impregnating Substances: Roots vacuum pumps are compatible with a wide range of impregnating substances, including resins, oils, solvents, and other liquids. They can handle different chemical compositions and provide a clean and efficient environment for the impregnation process.

4. Considerations for Vacuum Impregnation:

– Material Compatibility: It is essential to consider the compatibility of the porous material with the impregnating substance and the impregnation process itself. Some materials may require pre-treatment or surface preparation before impregnation. The choice of impregnating substance should also align with the material’s properties and intended application.

– Process Parameters: Vacuum impregnation involves controlling various process parameters, such as vacuum level, impregnation time, pressure release, and curing conditions. These parameters may vary depending on the material, impregnating substance, and desired impregnation results. Proper process optimization and control are crucial for achieving consistent and reliable impregnation outcomes.

– System Design: The design of the vacuum impregnation system should consider factors such as chamber size, gas flow rates, vacuum pump capacity, and pressure control mechanisms. Proper system design ensures efficient operation, reliable vacuum conditions, and effective impregnation of the porous material.

In summary, Roots vacuum pumps are well-suited for vacuum impregnation in manufacturing. Their high pumping speed, large volume handling capability, continuous operation, and compatibility with impregnating substances make them effective in creating and maintaining the required vacuum conditions for successful impregnation. By considering material compatibility, process parameters, and system design, Roots vacuum pumps contribute to the efficient and reliable impregnation of porous materials in various manufacturing applications.

What Is a Roots Vacuum Pump, and How Does It Work?

A Roots vacuum pump, also known as a Roots blower or a rotary lobe pump, is a type of positive displacement vacuum pump that is widely used for various industrial applications. Here’s a detailed explanation of what a Roots vacuum pump is and how it works:

A Roots vacuum pump consists of two synchronized rotors, known as lobes or impellers, that rotate in opposite directions within a housing. The lobes have a unique helical shape with multiple lobes, which allows them to trap and move gas efficiently. The rotors are synchronized with the help of timing gears to maintain precise clearances between the lobes and the housing.

The operation of a Roots vacuum pump can be described in the following steps:

1. Inlet Stage: The process begins with the lobes rotating in opposite directions. As the lobes rotate, the volume between them and the housing gradually increases, creating a larger space at the inlet side of the pump. This expansion of the volume causes the gas to enter the pump through the inlet port. The gas is drawn in due to the pressure difference between the inlet and the pump’s internal chamber.

2. Compression Stage: As the gas enters the pump, it gets trapped in the spaces between the lobes and the housing. As the lobes continue to rotate, the trapped gas gets carried along the rotating lobes. The gas is essentially trapped in the pockets formed by the lobes and the housing. The rotating lobes then compress the gas as they move towards the outlet side of the pump.

3. Outlet Stage: As the lobes approach the outlet side of the pump, the volume between them and the housing decreases, resulting in the compression of the trapped gas. This compression raises the pressure of the gas, causing it to be expelled through the outlet port of the pump. The expelled gas is then discharged into the atmosphere or directed to a downstream process or another vacuum pump, depending on the application.

It’s important to note that a Roots vacuum pump operates as a non-contacting pump, meaning that there is no physical contact between the lobes or between the lobes and the housing. This characteristic eliminates the need for lubrication within the pump and reduces the risk of contamination or oil vapor backstreaming into the vacuum system.

Roots vacuum pumps are known for their high pumping speed and ability to handle large volumes of gas. However, they are not capable of achieving high vacuum levels on their own. To achieve higher vacuum levels, a Roots pump is often used in conjunction with other vacuum pumps, such as rotary vane pumps or diffusion pumps, in a hybrid or combination pumping system.

In summary, a Roots vacuum pump operates based on the principle of positive displacement. It utilizes synchronized rotating lobes to trap and compress gas, allowing it to be discharged at a higher pressure. The non-contacting design of the pump eliminates the need for lubrication and reduces the risk of contamination. Roots vacuum pumps are commonly employed in various industrial applications, especially when high pumping speed and large gas handling capacity are required.

editor by CX 2024-04-13

China Best Sales Roots Pump, Liquid (Water) Ring Vacuum Pump, Air Pump, Oil-Less Piston Vacuum Pump, Nash, Sliding Vane Rotary Vane Vacuum Pump with Good quality

Product Description

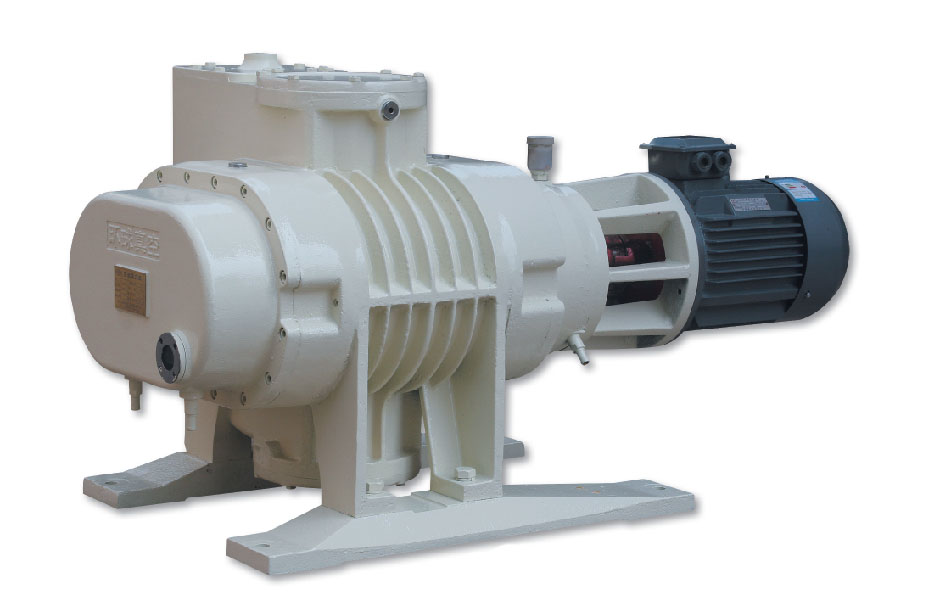

Product Description

Roots pump is a kind of vacuum pump without internal compression. It is a vacuum pump that realizes air extraction by moving gas under the pushing action of synchronous and reverse rotation of a pair of “8” shaped rotors in the pump cavity. Generally, the pumping rate is large and the power of the motor is small, so the front pump is required to pre pump. After the front pump reaches the specified vacuum degree, start the roots vacuum pump to improve the pumping speed and vacuum degree. Its structure and working principle are similar to roots blower. During operation, its suction is connected with the evacuated container or the main pump of vacuum system. There is no contact between rotors of Roots vacuum pump and between rotors and pump casing.

Our Advantages

The running parts in the pump have no friction, no lubrication, and there is no oil in the pump cavity, so a clean vacuum can be obtained.

2 leaf involute cycloid profile, high-precision machining to ensure smooth and quiet operation.

the gas in the pump chamber flows vertically, which is conducive to the discharge of dust and condensate in the pumped gas.

. The high-strength rotor with complete symmetry and precise dynamic balance operates stably and reliably.

high precision gear, imported bearing, low vibration and noise.

the new omni-directional three-dimensional water-cooling jacket design can effectively cool the pump body and greatly prolong the service life of the pump.

the overflow surface can be plated with shackles, Hastelloy and PTFE, which can adapt to corrosive environments with different strengths.

it is convenient to form roots vacuum unit with liquid ring vacuum pump, rotary vane vacuum pump and dry vacuum pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Pumping Speed L/S | Maximum allowable differential pressure (Pa) | Pump Speed(RPM) | Inlet Diameter(mm) | Outlet Diameter(mm) | Motor Power(kw) |

| ZJB-70 | 70 | 8000 | 2850 | 80 | 50 | 1.5 |

| ZJB-150 | 150 | 6000 | 2850 | 100 | 80 | 3 |

| ZJB-300 | 300 | 5000 | 2900 | 150 | 100 | 4 |

| ZJB-600 | 600 | 4000 | 2900 | 200 | 150 | 5.5Z7.5 |

| ZJ-1200 | 1200 | 3000 | 2900 | 250 | 200 | 11/15 |

| ZJ-2500 | 2500 | 2600 | 2900 | 300 | 250 | 22 |

| ZJ-3750 | 3750 | 2600 | 1450 | 350 | 350 | 30 |

| ZJ-5000 | 5000 | 2600 | 1450 | 400 | 400 | 45 |

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

New plant plHangZhou

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

High precision machining equipment

The company cooperates with many scientific research institutions and universities, such as ZheJiang University, China University of petroleum, ZheJiang Institute of mechanical design, etc.with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents.Our technology is leading, the product quality is stable, the product has a good reputation in China’s domestic market, is sold all over the country, and is exported to Europe, America, Africa, the Middle East and Southeast Asia,We adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

Product quality wins consumer cooperation

In shipment

ISO9001

High tech enterprise certificate

Welcome to send your needs, we will provide you with the best service,

provide the greatest help!!!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | One Year |

|---|---|

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Mainsuction Pump |

| Customization: |

Available

|

|

|---|

Can Roots Vacuum Pumps Be Used for Vacuum Impregnation in Manufacturing?

Yes, Roots vacuum pumps can be used for vacuum impregnation in manufacturing. Here’s a detailed explanation:

1. Vacuum Impregnation in Manufacturing: Vacuum impregnation is a process used in manufacturing to fill porous materials or components with a liquid or resin. It is commonly employed to enhance the properties of materials by improving their strength, sealing capability, or resistance to chemicals or corrosion. The process involves placing the porous material in a vacuum chamber and removing the air or gas trapped within its pores. Once a vacuum is established, a liquid or resin is introduced, and the vacuum is released, allowing the material to absorb the impregnating substance.

2. Role of Roots Vacuum Pumps: Roots vacuum pumps play a crucial role in the vacuum impregnation process by creating and maintaining the required vacuum conditions. Here’s how they contribute:

– Evacuation: Roots pumps are used to evacuate the impregnation chamber, removing the air and gas from within the pores of the porous material. By creating a vacuum, the trapped gases are extracted, creating a void space for the impregnating substance to penetrate.

– Pressure Control: Roots pumps help control the pressure within the impregnation chamber during different stages of the process. They can rapidly achieve and maintain the desired vacuum level, ensuring proper impregnation of the material and preventing the formation of air bubbles or voids.

– Gas Removal: Roots pumps effectively remove gases released from the impregnating substance during the impregnation process. As the liquid or resin fills the pores of the porous material, gases may be released due to the reaction or outgassing. The vacuum pump evacuates these gases, preventing their accumulation and ensuring complete impregnation.

3. Advantages of Roots Vacuum Pumps for Vacuum Impregnation:

– High Pumping Speed: Roots vacuum pumps have a high pumping speed, enabling rapid evacuation of the impregnation chamber. This reduces the overall impregnation cycle time, increasing manufacturing throughput and efficiency.

– Large Volume Handling: Roots pumps are capable of handling large volumes of gas, allowing them to evacuate chambers of different sizes effectively. This is advantageous when impregnating large or complex-shaped components that require a significant amount of impregnating substance.

– Continuous Operation: Roots pumps can operate continuously, maintaining the vacuum conditions required for impregnation throughout the process. This ensures consistent impregnation results and reduces the risk of incomplete impregnation or material defects.

– Compatibility with Impregnating Substances: Roots vacuum pumps are compatible with a wide range of impregnating substances, including resins, oils, solvents, and other liquids. They can handle different chemical compositions and provide a clean and efficient environment for the impregnation process.

4. Considerations for Vacuum Impregnation:

– Material Compatibility: It is essential to consider the compatibility of the porous material with the impregnating substance and the impregnation process itself. Some materials may require pre-treatment or surface preparation before impregnation. The choice of impregnating substance should also align with the material’s properties and intended application.

– Process Parameters: Vacuum impregnation involves controlling various process parameters, such as vacuum level, impregnation time, pressure release, and curing conditions. These parameters may vary depending on the material, impregnating substance, and desired impregnation results. Proper process optimization and control are crucial for achieving consistent and reliable impregnation outcomes.

– System Design: The design of the vacuum impregnation system should consider factors such as chamber size, gas flow rates, vacuum pump capacity, and pressure control mechanisms. Proper system design ensures efficient operation, reliable vacuum conditions, and effective impregnation of the porous material.

In summary, Roots vacuum pumps are well-suited for vacuum impregnation in manufacturing. Their high pumping speed, large volume handling capability, continuous operation, and compatibility with impregnating substances make them effective in creating and maintaining the required vacuum conditions for successful impregnation. By considering material compatibility, process parameters, and system design, Roots vacuum pumps contribute to the efficient and reliable impregnation of porous materials in various manufacturing applications.

What Are the Advantages of Using Roots Vacuum Pumps?

Roots vacuum pumps, also known as Roots blowers or rotary lobe pumps, offer several advantages that make them a popular choice for various industrial applications. Here’s a detailed explanation of the advantages of using Roots vacuum pumps:

1. High Pumping Speed: Roots vacuum pumps are known for their high pumping speed, which refers to the rate at which they can remove gas from a vacuum system. The unique design of synchronized rotating lobes enables these pumps to handle large volumes of gas efficiently. This high pumping speed makes Roots vacuum pumps well-suited for applications that require rapid evacuation or continuous extraction of gases.

2. Large Gas Handling Capacity: Roots vacuum pumps have a large gas handling capacity, allowing them to handle a wide range of gases, including clean air, corrosive gases, and vapors. Their robust construction and ability to handle gas with particulates or liquids make them suitable for applications in industries such as chemical processing, pharmaceuticals, food processing, and wastewater treatment.

3. Oil-Free and Contamination-Free Operation: One of the significant advantages of Roots vacuum pumps is that they operate without the need for lubrication. The non-contacting design of the pump eliminates the risk of oil contamination in the vacuum system. This is particularly important in applications where clean, oil-free vacuum environments are required, such as semiconductor manufacturing, electronics, and research laboratories.

4. Reliable and Low Maintenance: Roots vacuum pumps are known for their reliability and low maintenance requirements. Since there is no lubrication or contact between the lobes, there is minimal wear and tear, reducing the need for frequent maintenance or replacement of parts. This results in reduced downtime and lower operating costs for the users.

5. Noise and Vibration Reduction: Roots vacuum pumps are designed to operate with low noise and vibration levels. The precision engineering and balanced rotation of the lobes help minimize noise generation and vibration transmission. This makes Roots vacuum pumps suitable for applications where noise reduction and vibration control are important, such as in laboratories, medical facilities, and residential areas.

6. Wide Range of Vacuum Levels: While Roots vacuum pumps are not capable of achieving high vacuum levels on their own, they can be combined with other vacuum pumps, such as rotary vane pumps or diffusion pumps, to create hybrid or combination pumping systems. This allows them to cover a wide range of vacuum levels, making them versatile and adaptable to different application requirements.

7. Energy Efficiency: Roots vacuum pumps are designed to be energy-efficient, offering a favorable power-to-pumping speed ratio. Their efficient design and minimal internal losses help reduce energy consumption, resulting in lower operating costs for the users. This makes them an economical choice for continuous or high-throughput processes that require significant vacuum power.

8. Versatility and Compatibility: Roots vacuum pumps are compatible with various gases and can be used in a wide range of industrial applications. They find applications in industries such as chemical processing, pharmaceuticals, food processing, automotive, packaging, and environmental technology. Their versatility and compatibility make them suitable for both rough vacuum applications and as part of complex vacuum systems.

In summary, the advantages of using Roots vacuum pumps include high pumping speed, large gas handling capacity, oil-free and contamination-free operation, reliability, low maintenance requirements, noise and vibration reduction, a wide range of vacuum levels, energy efficiency, versatility, and compatibility. These advantages make Roots vacuum pumps a preferred choice for many industrial processes that require efficient and reliable vacuum generation.

editor by CX 2024-04-09

China supplier Water Ring Vacuum Pump Price 2be Sk 2sk 2BV Roots Air Pump Oil-Less Piston CHINAMFG Sliding Vane Rotary Vane Pump vacuum pump adapter

Product Description

Product Description

2BE series water ring vacuum pump and compressor, based on many years of scientific research results and production experience, combined with the international advanced technology of similar products, developed high efficiency and energy saving products, usually used for pumping no CHINAMFG particles, insoluble in water, no corrosion gas, in order to form a vacuum and pressure in a closed container. By changing the structure material, it can also be used to suck corrosive gas or to use corrosive liquid as working fluid. Widely used in papermaking, chemical, petrochemical, light industry, pharmaceutical, food, metallurgy, building materials, electrical appliances, coal washing, mineral processing, chemical fertilizer and other industries.

This series of pumps uses the CHINAMFG single action structure, has the advantages of simple structure, convenient maintenance, reliable operation, high efficiency and energy saving, and can adapt to large displacement, load impact fluctuation and other harsh conditions.

The key components, such as the distribution plate, impeller and pump shaft, have been optimized to simplify the structure, improve the performance and achieve energy saving. The welding impeller is used, the blade is pressed and formed once, and the shape line is reasonable; Hub processing, fundamentally solve the dynamic balance problem. Impeller and pump shaft are fitted with hot filling interference, reliable performance. It runs smoothly. After the impeller is welded, the whole is subjected to good heat treatment, and the blade has good toughness, so that the impact resistance and bending resistance of the blade can be fundamentally guaranteed, and it can adapt to the bad working conditions of load impact fluctuation.

2BE series pump, with air and water separator, multi-position exhaust port, pump cover is provided with exhaust valve overhaul window, impeller and distribution plate clearance through positioning bearing gland at both ends of the adjustment, easy to install and use, simple operation, easy maintenance.

Pump structure

The performance curve of this series of pumps is measured under the following working conditions: the suction medium is 20°C saturated air, the working liquid temperature is 15°C, the exhaust pressure is 1013mbar, and the deviation of soil is 10%.

Structure declaration

2BEA-10-25 Structure diagram

1.Flat key 2. Shaft 3. Oil deflector 4. Bearing cap 5. Bearings 6. Bearing bracket 7.Brasque cover

8.Brasque body 9. Brasque ring 10. Brasque 11.Valve plate 12. Valve block

13.Front distribution plate 14.Pump body 15. Impeller 16. O seal ring.

17.Back distribution plate 18. Side cover. 19. Flat key 20. Axle sleeve 21. Elastic collar

22.Water retaining ring 23. Adjusting washer 24. Rear bearing body 25. Bearing screw cap

26.Bearing 27. Bolt

2BEA-30-70 Structure diagram

1.Flat key 2. Shaft 3. Oil deflector 4. Front bearing retainer 5. Front bearing body

6. Front bearing inner cover 7. Front side cover 8. Brasque cover 9. Brasque body 10. Brasque ring

11. Brasque 12. Front distribution plate 13. Pump body 14. Impeller 15. O seal ring

16. Valve block 17. Valve plate 18. Back distribution plate 19. Axle sleeve 20. Flat key

21. Back side cover 22. Water retaining ring 23. Rear bearing inner cover 24. Bearing

25. Adjusting washer 26. Oil block 27. Rear bearing outer cover 28. Back bearing body

29. Oil baffle disc 30. Elastic retainer or circular spiral

Product Parameters

| Model | 2BEA SERIES | |

| Minimum suction absolute pressure (hPa) | 33-160 | |

| Suction intensity(m³/min) | Absolute inhalation capacity 60hPa | 3,95-336 |

| Absolute inhalation capacity 100hPa | 4.58-342 | |

| Absolute inhalation capacity 200hPa | 4.87-352 | |

| Absolute inhalation capacity 400hPa | 4.93-353 | |

| Max. shaft power(kw) | 7-453 | |

| Motor power(kw) | 11-560 | |

| Speed(rpm) | 197-1750 | |

| Weight(kg) | 235-11800 | |

| Size | 795*375*355mm-3185*2110*2045mm | |

| Model | 2BEC SERIES | |

| Minimum suction absolute pressure (hPa) | 160 | |

| Suction intensity(m³/min) | Absolute inhalation capacity 60hPa | 63-1700 |

| Absolute inhalation capacity 100hPa | 64-1738 | |

| Absolute inhalation capacity 200hPa | 65-1785 | |

| Absolute inhalation capacity 400hPa | 67-1800 | |

| Absolute inhalation capacity 550hPa | 68-1830 | |

| Max. shaft power(kw) | 61-2100 | |

| Motor power(kw) | 75-2240 | |

| Speed(rpm) | 105-610 | |

| Weight(kg) | 2930-57500 | |

| Size | 2102*1320*1160mm-5485*3560*3400mm | |

Detailed Photos

Operation site

Company presentation

Product gallery

RFQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral export wooden case . If you have legally registered patent, we can pack the goods in

wooden case with your own marks after getting your authorization letters.

Q2. What is your termsof payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, etc.

Q4. How about your delivery time?

A: Generally, it will take from 10 dasys to 30 days after receiving your advance payment according to the pump’s material. The

specific delivery time also depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test the pumps before delivery .

Q8: How do you make our business long-term and good relationship?

A. We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they are from. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online |

|---|---|

| Warranty: | 1 Years |

| Oil or Not: | Oil Free |

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Kinetic Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

How Do You Select the Right Size Roots Vacuum Pump for a Specific Application?

Selecting the right size Roots vacuum pump for a specific application requires careful consideration of various factors. Here’s a detailed explanation:

1. Determine the Required Pumping Speed: The pumping speed is a crucial parameter that indicates the volume flow rate of gas that the Roots vacuum pump can handle. To select the right size pump, you need to determine the required pumping speed for your application. Consider factors such as the volume of the system being evacuated, the gas load, and the desired evacuation time. The required pumping speed will help narrow down the options and identify pumps that can meet your application’s demands.

2. Consider the Ultimate Vacuum Level: The ultimate vacuum level is the lowest pressure that the Roots vacuum pump can achieve under ideal conditions. Different applications have varying vacuum level requirements. Determine the desired ultimate vacuum level for your application, keeping in mind factors such as the sensitivity of the process, the presence of moisture or contaminants, and the specific requirements of the downstream equipment or processes. Ensure that the selected pump can reach the required vacuum level.

3. Evaluate Gas Composition and Characteristics: The composition and characteristics of the gas being pumped are essential considerations. Some gases, such as condensable vapors or corrosive gases, may require special pump features or materials to ensure efficient and safe operation. Consider the gas composition, including its chemical properties, temperature, and any potential challenges it may pose to the pump’s performance or longevity. Consult the pump manufacturer or specialist for guidance on selecting a pump suitable for handling the specific gas or gas mixture in your application.

4. Account for System Constraints and Operating Conditions: Assess the system constraints and operating conditions that may impact the pump’s performance. Factors such as the available space for the pump, power supply requirements, cooling options, and noise limitations should be taken into consideration. Additionally, consider any specific operating conditions such as temperature extremes, high-altitude operation, or continuous-duty requirements. Ensure that the selected pump is compatible with the system constraints and can operate reliably under the anticipated operating conditions.

5. Consult Manufacturer Specifications and Performance Curves: Review the manufacturer’s specifications and performance curves for the Roots vacuum pumps under consideration. These documents provide detailed information about the pump’s capabilities, operating ranges, and performance characteristics. Pay attention to parameters such as pumping speed, ultimate vacuum level, power requirements, and any specific features or limitations. Compare the specifications with your application requirements to identify pumps that align with your needs.

6. Seek Expert Advice: If you are unsure about the pump selection process or have complex application requirements, it is recommended to seek advice from pump manufacturers or specialists. They can provide valuable insights, recommend suitable pump models, and assist in evaluating your specific application needs.

7. Consider Future Expansion and Flexibility: When selecting a Roots vacuum pump, consider the potential for future expansion or changes in your application. If there is a possibility of increased gas load or system requirements in the future, it may be advantageous to select a slightly larger pump to accommodate potential growth and ensure long-term suitability.

In summary, selecting the right size Roots vacuum pump involves determining the required pumping speed, considering the ultimate vacuum level, evaluating gas composition and characteristics, accounting for system constraints and operating conditions, consulting manufacturer specifications, and seeking expert advice when needed. By carefully considering these factors, you can choose a Roots vacuum pump that meets the specific requirements of your application, ensuring efficient and reliable operation.

Are Roots Vacuum Pumps Used in Industrial Applications?

Yes, Roots vacuum pumps are widely used in various industrial applications. Here’s a detailed explanation of their application in industrial settings:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are just a few examples of the industrial applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by CX 2024-04-04

China wholesaler Liquid (Water) Ring Vacuum Pump, Roots Pump, Air Pump, Oil-Less Piston Vacuum Pump, Nash, Sliding Vane Rotary Vane Vacuum Pump vacuum pump belt

Product Description

Product Description

SK series water ring vacuum spring and compressor is used to suck or compress air and other non-corrosive, insoluble in water, does not contain CHINAMFG particles of the gas body, in order to form a vacuum and pressure in a closed container, suction gas allowed to mix a small amount of liquid.

Scope of application

SK water ring vacuum pumps and compressors are widely used in machinery, petrochemical, pharmaceutical, food, sugar industry and electronic fields. Because in the working process, the gas compression process is isothermal, so in the compression and patting explosive gas, not prone to danger, so its application more widely.

Product Parameters

| Model | Pumping capacity(fTp/min) | Limit pressure of vacuum pump | Motor power (KW) | Pump RPM(r/m) | Compressor pressure | Caliber (mm) | ||||

| Max. | Suction pressure is 0.041 MPa | mmHg | MPa | Vacuum pump | Compressor | In | Out | |||

| SK-0.15 | 0.15 | 0.135 | -650 | -0.087 | 0.55 | 1 | 2860 | / | G3/4″ | G3/4″ |

| SK-0.4 | 0.4 | 0.36 | -650 | -0.087 | 1.5 | 1 | 2860 | 1 | G1″ | G1″ |

| SK-0.8 | 0.8 | 0.72 | -650 | -0.087 | 2.2 | 1 | 2860 | 1 | G1″ | G1″ |

| SK-1.5B | 1.5 | 1.35 | -680 | -0.091 | 4 | 1 | 2860 | / | G1 1/4″ | G1 1/4″ |

| SK-1.5 | 1.5 | 1.35 | -680 | -0.091 | 4 | 4 | 1440 | 0-0.1 | 70 | 70 |

| SK-3 | 3 | 2.8 | -700 | -0.093 | 5.5 | 7.5 | 1440 | 0-0.1 | 70 | 70 |

| SK-6 | 6 | 5.4 | -700 | -0.093 | 11 | 15 | 1460 | 0-0.1 | 80 | 80 |

| SK-9 | 9 | 8.1 | -700 | -0.093 | 15 | 22 | 970 | 0-0.1 | 80 | 80 |

| SK-12 | 12 | 10.8 | -700 | -0.093 | 18.5 | 30 | 970 980 | 0-0.1 | 80 | 80 |

| SK-15 | 15 | 13.5 | -700 | -0.093 | 30 | 45 | 980 | 0-0.1 | 80 | 80 |

| SK-20 | 20 | 18 | -700 | -0.093 | 37 | 55 | 740 | 0-0.1 | 150 | 150 |

| SK-30 | 30 | 27 | -700 | -0.093 | 55 | 75 | 740 | 0-0.1 | 150 | 150 |

| SK-42 | 42 | 37.8 | -700 | -0.093 | 75 | 1 | 740 | 1 | 150 | 150 |

| SK-60 | 60 | 54 | -700 | -0.093 | 90 | 1 | 590 | 1 | 250 | 250 |

| SK-85 | 85 | 76.5 | -700 | -0.093 | 132 | 1 | 590 | 1 | 250 | 250 |

| SK-120 | 120 | 108 | -700 | -0.093 | 185 | 1 | 490 | 1 | 300 | 300 |

Noted:

1. Intramuscular values are derived under the following conditions:

Atmospheric pressure 0.1013MPa

The water temperature is 15°C

The air temperature is 20°C

Relative humidity of gas 70%

2. The deviation of pumping volume is not more than ±10%

Detailed Photos

Customer usage display

Certifications

Factory overview

Warehouse overview

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Years |

|---|---|

| Oil or Not: | Oil Free |

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Kinetic Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Work Function: | Mainsuction Pump |

| Customization: |

Available

|

|

|---|

Can Roots Vacuum Pumps Be Used for Environmental Testing in Chambers?

Yes, Roots vacuum pumps can be used for environmental testing in chambers. Here’s a detailed explanation:

1. Environmental Testing in Chambers: Environmental testing involves subjecting a product or component to various simulated environmental conditions to assess its performance, durability, and reliability. Chambers are commonly used for environmental testing and can simulate conditions such as temperature, humidity, pressure, and gas composition. These chambers create controlled environments that mimic real-world operating conditions to evaluate how a product or component responds under different environmental stressors.

2. Role of Vacuum Pumps: Vacuum pumps play a crucial role in environmental testing chambers by creating and maintaining the desired vacuum conditions. They help establish specific pressure levels, remove unwanted gases or contaminants, and enable controlled gas flow within the chamber. Vacuum pumps are responsible for evacuating the chamber, achieving the desired pressure or vacuum level, and ensuring the accuracy and reliability of the environmental test results.

3. Advantages of Roots Vacuum Pumps: Roots vacuum pumps offer several advantages that make them suitable for environmental testing in chambers:

– High Pumping Speed: Roots pumps have a high pumping speed, allowing them to quickly evacuate the chamber and achieve the desired vacuum level. This is particularly important when rapid cycling between different test conditions is required.

– Large Volume Handling: Chambers used in environmental testing can vary in size, from small-scale chambers to large walk-in chambers. Roots vacuum pumps are capable of handling large volumes of gas, making them suitable for evacuating chambers of different sizes efficiently.

– Continuous Operation: Roots vacuum pumps can operate continuously, ensuring the chamber remains at the desired vacuum level throughout the testing process. This is essential for maintaining test accuracy and consistency.

– Compatibility with Hybrid Pumping Systems: Roots vacuum pumps can be integrated into hybrid pumping systems, working alongside other pump technologies such as rotary vane pumps, scroll pumps, or turbomolecular pumps. This combination allows for enhanced pumping capability, achieving the desired vacuum levels and accommodating specific test requirements.

4. Considerations for Environmental Testing: While Roots vacuum pumps are suitable for environmental testing, several considerations should be taken into account:

– Gas Composition: Different environmental tests may involve specific gas compositions or mixtures. It is important to ensure that the selected Roots pump is compatible with the gases used in the testing process. Some gases may require special pump features or materials to avoid contamination or damage to the pump.

– Pressure Range: Environmental testing chambers may require a wide range of pressure levels to simulate various conditions. Roots vacuum pumps have limitations in terms of the ultimate vacuum level they can achieve. It is necessary to ensure that the selected pump can meet the pressure range requirements of the specific environmental tests.

– System Design: Proper system design is crucial to ensure efficient and reliable operation of the environmental testing chamber. Factors such as the chamber size, gas flow rates, evacuation times, and pressure control mechanisms should be considered when selecting and integrating Roots vacuum pumps into the testing system.

In summary, Roots vacuum pumps can be effectively used for environmental testing in chambers. Their high pumping speed, large volume handling capability, continuous operation, and compatibility with hybrid pumping systems make them suitable for maintaining the desired vacuum conditions during environmental tests. By considering factors such as gas composition, pressure range, and system design, Roots vacuum pumps contribute to the accurate and reliable assessment of product performance under simulated environmental conditions.

What Are the Primary Applications of Roots Vacuum Pumps?

Roots vacuum pumps, also known as Roots blowers or rotary lobe pumps, are utilized in a variety of industrial applications where efficient and reliable vacuum generation is required. Here’s a detailed explanation of the primary applications of Roots vacuum pumps:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are some of the primary applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by CX 2024-04-03

China Good quality Vacuum Pump Air Rotary Roots Liquid-Ring Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps manufacturer

Product Description

Vacuum Pump Air Rotary Roots Liquid-Ring Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps

VP roots vacuum pump is in the 50 Torr-micron high vacuum range has a large pumping speed and low cost of equipment, it can be combined with various vacuum pump consists of a vacuum unit. KMBD roots vacuum pump with 5 point bearing design unique, sealing the five bit machine, sealing double sealing structure + mechanical seal for maze, can realize non leakage, reduce maintenance and repair of the link, ensure the roots pump and durable. Synchronous helical gear and mounted on the driving end, both to ensure quiet and reliable operation, and can reduce the load of the rotor torque. Impeller and shaft integrally cast, can provide large size shaft, impeller and reduce the risk of damage. All contact with the sealing surface of the shaft end faces are polished to reduce wear and reduce the risk of leakage, high temperature high pressure casing, and double tank design, a variety of material selection, further to ensure that the use of the user in various working conditions. Typical application: chemical, petrochemical, plastics, semiconductors, wood mixture, food processing, vacuum furnace, vacuum booster system, vacuum drying, vacuum dewatering, vacuum packaging

Typical Applications

Special structures working principles,suitable for operation in chemical industry,oil industry,food industry,electrical utility industry,pharmacy industry,textile industry and paper making industry,etc. The other industries that need vacuum drying,concentration,distilling,dehydration and filtering also need the water-ring vacuum pump. It can be use as a backing pump of Roots Pump.

Specifications

| Model | Capacity | Ultimate Pressure | Power | speed |

| L/S | Pa | KW | RPM | |

| VP200 | 200 | 0.05 | 4 | 2900 |

| VP600 | 600 | 0.05 | 7.5 | 2900 |

Characteristic Curves

Overall Dimensions

company information

| After-sales Service: | Installation Guide 1-Year Warranty |

|---|---|

| Warranty: | Installation Guide 1-Year Warranty |

| Oil or Not: | Optional |

| Structure: | – |

| Exhauster Method: | – |

| Vacuum Degree: | – |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

How Are Roots Vacuum Pumps Utilized in the Automotive Industry?

Roots vacuum pumps play a significant role in various applications within the automotive industry. Here’s a detailed explanation:

1. Brake System Vacuum Pumps:

– Vacuum Boosters: Roots vacuum pumps are commonly used as vacuum boosters in automotive brake systems. They assist in enhancing the braking performance by providing the necessary vacuum for power brake operation. When the driver applies the brake pedal, the vacuum booster uses the suction power generated by the Roots pump to amplify the force applied to the brake master cylinder, resulting in more effective braking.

– Electric Brake Vacuum Pumps: In modern electric or hybrid vehicles, where traditional engine-driven vacuum sources may not be available, electric brake vacuum pumps are utilized. These pumps, often based on the Roots principle, generate vacuum independently to power the brake booster and ensure reliable braking performance.

2. Emissions Control:

– Evaporative Emission Control: Roots vacuum pumps are employed in evaporative emission control systems to prevent the release of harmful vapors from the fuel system into the atmosphere. These pumps create a vacuum within the system, purging and storing fuel vapors in a canister for subsequent combustion or recycling.

– Positive Crankcase Ventilation (PCV): PCV systems, which are designed to reduce emissions and maintain the integrity of the engine, also utilize Roots vacuum pumps. These pumps draw crankcase gases and vapors, including oil mist, from the engine’s crankcase into the intake manifold for combustion, improving overall engine efficiency and reducing pollution.

3. Engine Testing and Development:

– Vacuum Leakage Testing: Roots vacuum pumps are utilized for vacuum leakage testing in engine manufacturing and development. By creating a vacuum in the intake manifold or other engine components, these pumps enable the detection of leaks and ensure the integrity of the engine’s air delivery system.

– Air Flow Calibration: During engine testing and calibration, Roots vacuum pumps are used to simulate various operating conditions by controlling the intake air flow. This allows engineers to fine-tune the engine’s performance, optimize fuel-air mixture ratios, and assess the engine’s efficiency and emissions characteristics.

4. HVAC Systems: