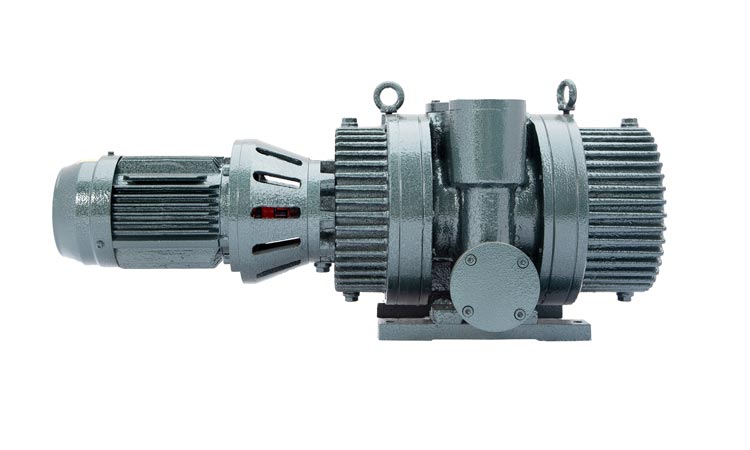

Product Description

2BV Vacuum pump

OIL ROTARY VANE VACUUM PUMP,DRY ROTARY VANE VACUUM PUMP,

Liquid Ring Vacuum Pumps,Roots Vacuum Pump,Screw Vacuum Pump,Vacuum Pump System

2BV Vacuum pump Application

Automotive Industry, Biofuel Industry, Commercial Buildings, Developing World Water Solutions, District Energy, Drinking water treatment, Food and Beverage Industry, Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Raw Water Intake, temperature control, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Distribution, Water Treatment Solutions,

Other Pressure High pressure

Voltage 220V/380V/440V/As customer request

2BV series water ring vacuum pump is an integral structure-pump coaxial single-stage pump. The shaft seal adopts mechanical seal, which has the characteristics of simple structure, simple installation, oil-free, safe and reliable, etc.

2BV series water ring vacuum pump is suitable for removing gas and moist steam, and the suction pressure can reach 33mbar absolute pressure (97% vacuum). When 2BV water ring vacuum pump works for a long time when the suction pressure is lower than 80mbar, cavitation protection tube should be connected to protect the pump. If 2BV water ring vacuum pump is equipped with atmospheric injector, the suction pressure can reach 10mbar, and the injector can be installed directly on the suction port of vacuum pump. The maximum pressure is 0.26MPa (absolute pressure).

PRODUCT ANALYSIS

Product model

| Type | extreme pressure Mbar(Pa) | Maximum gas volume M3/min | Power KW | Speed Rmp | Water consumption L/min | Weight KG |

| 2BV-2060 | 33(3300) | 0.45 | 0.87 | 2880 | ~2 | 20 |

| 2BV-2061 | 33(3300) | 0.87 | 1.45 | 2880 | ~2 | 22 |

| 2BV-2070 | 33(3300) | 1.33 | 2.35 | 2880 | ~2.5 | 31 |

| 2BV-2071 | 33(3300) | 1.83 | 3.85 | 2880 | ~4.2 | 42 |

| 2BV-5110 | 33(3300) | 2.75 | 4 | 1450 | ~7 | 78 |

| 2BV-5111 | 33(3300) | 3.83 | 5.5 | 1450 | ~8.5 | 100 |

| 2BV-5121 | 33(3300) | 4.68 | 7.5 | 1450 | ~10 | 145 |

| 2BV-5131 | 33(3300) | 6.68 | 11 | 1450 | ~15 | 165 |

| 2BV-5161 | 33(3300) | 8.3 | 15 | 970 | ~20 | 252 |

| 2BV-6110 | 33(3300) | 2.75 | 4 | 1450 | ~7 | 107 |

| 2BV-6111 | 33(3300) | 3.83 | 5.5 | 1450 | ~8.5 | 142 |

| 2BV-6121 | 33(3300) | 4.68 | 7.5 | 1450 | ~10 | 198 |

| 2BV-6131 | 33(3300) | 6.68 | 11 | 1450 | ~15 | 238 |

| 2BV-6161 | 33(3300) | 8.3 | 15 | 970 | ~20 | 350 |

For more customization details, message supplier

2BV series water ring vacuum pumps and compressors are widely used in petroleum, chemical, pharmaceutical, food, sugar industry and other fields. Because the compression process of the gas is isothermal in the working process, it is not easy to explode when compressing and pumping flammable and explosive gas, so it is more widely used.

Customization

ONETER is 1 of the leading manufacturer for the Slurry pump & Coupler& Vacuum pump since 2571 year. Refund the money if you are not satified of the quality.

*100% quality guarantee.

*One-stop service for you.

*Factory competitive price.

*Fast delievery time with stocks.

WHY CHOOSE US?!

1.ONETER only supply competitive advantage products!

2.Full refund or Free replacement in case of bad quality or late delivery!

3.ONETER are focus on service for solution, not only supply screw barrel parts!

4.Quality is our culture, with us your money in safe your business in safe!!!

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral export wooden case . If you have legally registered patent, we can pack the goods in wooden case with your own marks after getting your authorization letters.

Q2. What is your termsof payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay

the balance.

Q3. How about your delivery time?

A: Generally, it will take from 10 dasys to 50 days after receiving your advance payment according to the pump’s material. The specific delivery time also depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do youtest all your goods before delivery?

A: Yes, we have 100% test the pumps before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One-Stop Service for You |

|---|---|

| Warranty: | 2 Years |

| Oil or Not: | Oil Free |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Do Roots Vacuum Pumps Affect the Efficiency of Vacuum Systems in Various Industries?

Roots vacuum pumps have a significant impact on the efficiency of vacuum systems across various industries. Here’s a detailed explanation:

1. Enhanced Vacuum Level:

– High Pumping Speed: Roots vacuum pumps are known for their high pumping speed, which refers to the rate at which they can evacuate gas from a system. By quickly removing gas molecules, these pumps help achieve and maintain a lower pressure, resulting in an enhanced vacuum level within the system. This increased vacuum level is crucial in industries such as semiconductor manufacturing, where precise control of pressure is necessary for optimal processing conditions.

– Improved Evacuation Time: With their rapid gas pumping capability, Roots vacuum pumps significantly reduce the evacuation time required to reach the desired vacuum level. This efficiency is particularly important in industries where time-sensitive processes are involved, such as vacuum drying, degassing, or impregnation, allowing for faster production cycles and increased productivity.

2. Increased Throughput:

– Continuous Operation: Roots vacuum pumps are designed for continuous operation, enabling uninterrupted gas removal from the vacuum system. Their robust construction and oil-free operation make them reliable and suitable for demanding industrial applications. The ability to maintain a consistent vacuum level without frequent stops or downtime contributes to increased system throughput and overall efficiency.

– Handling Large Volumes: Roots pumps are capable of handling large gas volumes due to their displacement principle. This makes them well-suited for industries that require the evacuation of substantial amounts of gas, such as in chemical processing, pharmaceutical manufacturing, or vacuum packaging. By efficiently evacuating large volumes of gas, Roots vacuum pumps facilitate higher production rates and improved process efficiency.

3. Improved Process Control:

– Stable Vacuum Level: Roots vacuum pumps help maintain a stable vacuum level within the system, which is essential for precise process control. By swiftly removing gas molecules, these pumps prevent pressure fluctuations and ensure a consistent environment for various manufacturing processes. This is particularly crucial in industries like thin film deposition, where maintaining a stable vacuum is crucial for achieving uniform coating thickness and quality.

– Reduced Contamination: Roots vacuum pumps operate without lubricating oil in the pumping chamber, minimizing the risk of oil contamination in the vacuum system. This is particularly advantageous in industries such as electronics, semiconductor fabrication, or research laboratories, where even trace amounts of contaminants can adversely affect product quality or experimental results. By providing clean and oil-free vacuum, Roots pumps contribute to improved process control, reduced yield loss, and enhanced product reliability.

4. Energy Efficiency:

– Lower Power Consumption: Roots vacuum pumps are designed to operate efficiently, consuming lower power compared to other types of vacuum pumps. This energy efficiency is beneficial in industries where vacuum systems are continuously operated, such as in chemical processing plants or industrial manufacturing facilities. By reducing power consumption, Roots pumps help lower operational costs and contribute to sustainable and environmentally friendly practices.

– Heat Dissipation: Roots pumps generate less heat during operation compared to certain other vacuum pump types. This is advantageous in industries where temperature control is critical, such as in semiconductor fabrication or vacuum furnaces. The reduced heat generation minimizes the need for additional cooling measures, improving overall energy efficiency and reducing operational costs.

In summary, Roots vacuum pumps significantly impact the efficiency of vacuum systems in various industries. They enhance the vacuum level, increase system throughput, improve process control, and contribute to energy savings. By providing high pumping speed, quick evacuation time, continuous operation, stable vacuum levels, reduced contamination risk, lower power consumption, and efficient heat dissipation, Roots vacuum pumps play a crucial role in optimizing the performance and productivity of vacuum systems across industries.

What Are the Primary Applications of Roots Vacuum Pumps?

Roots vacuum pumps, also known as Roots blowers or rotary lobe pumps, are utilized in a variety of industrial applications where efficient and reliable vacuum generation is required. Here’s a detailed explanation of the primary applications of Roots vacuum pumps:

1. Chemical Processing: Roots vacuum pumps find extensive use in the chemical processing industry. They are employed for processes such as vacuum distillation, solvent recovery, drying, and degassing. Their high pumping speed and ability to handle corrosive gases make them suitable for handling various chemical vapors and byproducts.

2. Pharmaceuticals: In the pharmaceutical industry, Roots vacuum pumps are utilized for applications such as vacuum drying, tablet coating, freeze drying, and vacuum packaging. Their oil-free operation ensures a clean and contaminant-free vacuum environment, which is crucial for pharmaceutical manufacturing processes.

3. Food Processing: Roots vacuum pumps play a significant role in the food processing industry. They are employed for vacuum packaging, vacuum cooling, and vacuum drying of food products. The oil-free operation of Roots vacuum pumps ensures food safety and eliminates the risk of contamination.

4. Environmental Technology: Roots vacuum pumps are utilized in environmental technology applications, including wastewater treatment, biogas processing, and air pollution control. They are employed to extract gases, control emissions, and facilitate the treatment and purification of air and water.

5. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps are used for processes such as ion implantation, physical vapor deposition (PVD), chemical vapor deposition (CVD), and etching. Their high pumping speed and oil-free operation are crucial for maintaining clean vacuum conditions required in semiconductor fabrication.

6. Packaging and Printing: Roots vacuum pumps are employed in packaging and printing applications. They are used for vacuum packaging of products, vacuum forming of packaging materials, and in printing presses for paper handling and ink transfer.

7. Automotive Industry: Roots vacuum pumps find application in the automotive industry for processes such as brake system vacuum assist, crankcase ventilation, and emissions control systems. They help create vacuum conditions required for the operation of various automotive systems.

8. Research and Laboratory: Roots vacuum pumps are utilized in research laboratories and scientific facilities for a wide range of applications. They are used in vacuum ovens, freeze dryers, vacuum filtration, electron microscopy, surface analysis, and other laboratory processes that require controlled vacuum environments.

9. Energy Industry: In the energy sector, Roots vacuum pumps are used for applications such as steam turbine condenser air extraction, transformer drying, and vacuum impregnation of electrical components. They help maintain proper vacuum conditions for efficient and reliable operation of energy systems.

These are some of the primary applications where Roots vacuum pumps are commonly used. Their high pumping speed, large gas handling capacity, oil-free operation, reliability, and versatility make them suitable for a wide range of industrial processes that require efficient and reliable vacuum generation.

editor by Dream 2024-05-08