Product Description

Product Description

|

Power |

Voltage |

Air volume |

Wind pressure |

Suction pressure |

|

3kw Ring Blower |

380v |

318m³/h |

38kpa |

35kpa |

|

4kw Ring Blower |

380v |

420m³/h |

45kpa |

41kpa |

|

5.5kw Ring Blower |

380v |

500m³/h |

50kpa |

48kpa |

|

7.5kw Ring Blower |

380v |

520m³/h |

56kpa |

51kpa |

1) Beautiful surface and Small dimensions in the die-cast aluminum alloy housing

2) Both 50Hz and 60Hz are available.

3) Dual-usage: Compressor and Vacuum (suction and blow).

4) Electronic motor with IP54 protection and Insulation class F.

5) 100% oil-free and no oily odors.

6) Low noise and libration.

7) Maintenance-free and easy installation.

8) Strong dynamic stability without vibration

9) Pulsation-free discharge

10) Cooler running bearings

11) Longer grease life

12) Suitable for environmental protection

13) Continuous duty

Company Profile

HangZhou CHINAMFG Bao Automation Equipment Co., Ltd.

From China to the world

Diaobao CNC Equipment Co., Ltd. is a company that integrates production, sales, and research and development. It is committed to providing automation equipment manufacturing for global users, and upholds the product development concept of high efficiency, intelligence, environmental protection, and compatibility. Since its establishment, Diaobao CNC has developed rapidly and has 2 standardized intelligent equipment manufacturing bases with a total area of over 10,000 square meters. We are focus on CNC Machine Parts.It is specialized in five-axis engraving machines, vibrating knife cutting machines, woodworking engraving machines, stone engraving machines, advertising engraving machines, mold precision engraving machines, and CNC engraving and milling machines. The products have passed ISO9001 certification and are reliable in quality and complete in variety. They are exported to the Middle East, Africa, South America, and other regions. They operate stably in the woodworking industry, model industry, mold industry, blister industry, packaging industry, clothing industry, automotive interior industry, leather cutting industry, etc. They have a wide range of benchmarking customer examples. Professional independent core research and development team and well-established after-sales technical department truly provide customer-centric service experience.

FAQ

1.About us

We are in HangZhou ZheJiang , which is the hometown of CNC Router. We are focus on CNC Machine Parts.

We’ve been in this business for more than 10 years.

2.What products do we have?

We have many CNC Machine Parts , include Spindle,Inverter,stepper motor,driver,guide rail,sliding block,

rack,gear box,water pump,dust collector,coupling,tool-setter,tool cutter. And so on …

3.How we guarantee the quality of the products?

Each batch of products will pass the test before leaving the factory.

Before delivery, we will check the list 1 by one.

4.Why you should choose us?

We are focus on CNC Router Parts more than 10years. We can provide you with the overall solution, We

can offer you many type CNC products.Just tell us which you need , we will provide you as the best price

and the best quality and service.

5.What’s the payment term?

We normally accept T/T, Western Union, L/C, and Paypal.

6.What about the shipping ?

We support multiple modes of transportation,such as by express,by air,by sea,by rail and so on.

Also can shipping by DHL\FedEx\TNT\UPS\EMS and so on.

We can offer different type transactions: FOB\EXW\FCA\DAP\CIF.

We can also help you to keep other suppliers goods at our warehouse and shipping together.

7.How to place an order?

Just tell us what you need , then we can make a Invoice for you. If all OK , then make the order and we

shipping to you the goods ASAP.

In order to ensure that all products are what you need, we will show you the pictures, drawings, videos

and so on before shipping .

8.What about the delivery time?

We have a large warehouse and most of our goods are in stock.When you have order, we can shipping

the goods fast.

Generally speaking, the time from our warehouse to the forwarder is about 2 days, and then the goods

can be sent by DHL FedEx UPS TNT to you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Timely After-Sales Service |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil |

| Structure: | Rotary Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How Do You Maintain and Troubleshoot Vacuum Pumps?

Maintaining and troubleshooting vacuum pumps is essential to ensure their optimal performance and longevity. Here’s a detailed explanation:

Maintenance of Vacuum Pumps:

1. Regular Inspection: Perform regular visual inspections of the pump to check for any signs of damage, leaks, or abnormal wear. Inspect the motor, belts, couplings, and other components for proper alignment and condition.

2. Lubrication: Follow the manufacturer’s guidelines for lubrication. Some vacuum pumps require regular oil changes or lubrication of moving parts. Ensure that the correct type and amount of lubricant are used.

3. Oil Level Check: Monitor the oil level in oil-sealed pumps and maintain it within the recommended range. Add or replace oil as necessary, following the manufacturer’s instructions.

4. Filter Maintenance: Clean or replace filters regularly to prevent clogging and ensure proper airflow. Clogged filters can impair pump performance and increase energy consumption.

5. Cooling System: If the vacuum pump has a cooling system, inspect it regularly for cleanliness and proper functioning. Clean or replace cooling components as needed to prevent overheating.

6. Seals and Gaskets: Check the seals and gaskets for signs of wear or leakage. Replace any damaged or worn seals promptly to maintain airtightness.

7. Valve Maintenance: If the vacuum pump includes valves, inspect and clean them regularly to ensure proper operation and prevent blockages.

8. Vibration and Noise: Monitor the pump for excessive vibration or unusual noise, which may indicate misalignment, worn bearings, or other mechanical issues. Address these issues promptly to prevent further damage.

Troubleshooting Vacuum Pump Problems:

1. Insufficient Vacuum Level: If the pump is not achieving the desired vacuum level, check for leaks in the system, improper sealing, or worn-out seals. Inspect valves, connections, and seals for leaks and repair or replace as needed.

2. Poor Performance: If the pump is not providing adequate performance, check for clogged filters, insufficient lubrication, or worn-out components. Clean or replace filters, ensure proper lubrication, and replace worn parts as necessary.

3. Overheating: If the pump is overheating, check the cooling system for blockages or insufficient airflow. Clean or replace cooling components and ensure proper ventilation around the pump.

4. Excessive Noise or Vibration: Excessive noise or vibration may indicate misalignment, worn bearings, or other mechanical issues. Inspect and repair or replace damaged or worn parts. Ensure proper alignment and balance of rotating components.

5. Motor Issues: If the pump motor fails to start or operates erratically, check the power supply, electrical connections, and motor components. Test the motor using appropriate electrical testing equipment and consult an electrician or motor specialist if necessary.

6. Excessive Oil Consumption: If the pump is consuming oil at a high rate, check for leaks or other issues that may be causing oil loss. Inspect seals, gaskets, and connections for leaks and repair as needed.

7. Abnormal Odors: Unusual odors, such as a burning smell, may indicate overheating or other mechanical problems. Address the issue promptly and consult a technician if necessary.

8. Manufacturer Guidelines: Always refer to the manufacturer’s guidelines and recommendations for maintenance and troubleshooting specific to your vacuum pump model. Follow the prescribed maintenance schedule and seek professional assistance when needed.

By following proper maintenance procedures and promptly addressing any troubleshooting issues, you can ensure the reliable operation and longevity of your vacuum pump.

What Is the Role of Vacuum Pumps in Pharmaceutical Manufacturing?

Vacuum pumps play a crucial role in various aspects of pharmaceutical manufacturing. Here’s a detailed explanation:

Vacuum pumps are extensively used in pharmaceutical manufacturing processes to support a range of critical operations. Some of the key roles of vacuum pumps in pharmaceutical manufacturing include:

1. Drying and Evaporation: Vacuum pumps are employed in drying and evaporation processes within the pharmaceutical industry. They facilitate the removal of moisture or solvents from pharmaceutical products or intermediates. Vacuum drying chambers or evaporators utilize vacuum pumps to create low-pressure conditions, which lower the boiling points of liquids, allowing them to evaporate at lower temperatures. By applying vacuum, moisture or solvents can be efficiently removed from substances such as active pharmaceutical ingredients (APIs), granules, powders, or coatings, ensuring the desired product quality and stability.

2. Filtration and Filtrate Recovery: Vacuum pumps are used in filtration processes for the separation of solid-liquid mixtures. Vacuum filtration systems typically employ a filter medium, such as filter paper or membranes, to retain solids while allowing the liquid portion to pass through. By applying vacuum to the filtration apparatus, the liquid is drawn through the filter medium, leaving behind the solids. Vacuum pumps facilitate efficient filtration, speeding up the process and improving product quality. Additionally, vacuum pumps can aid in filtrate recovery by collecting and transferring the filtrate for further processing or reuse.

3. Distillation and Purification: Vacuum pumps are essential in distillation and purification processes within the pharmaceutical industry. Distillation involves the separation of liquid mixtures based on their different boiling points. By creating a vacuum environment, vacuum pumps lower the boiling points of the components, allowing them to vaporize and separate more easily. This enables efficient separation and purification of pharmaceutical compounds, including the removal of impurities or the isolation of specific components. Vacuum pumps are utilized in various distillation setups, such as rotary evaporators or thin film evaporators, to achieve precise control over the distillation conditions.

4. Freeze Drying (Lyophilization): Vacuum pumps are integral to the freeze drying process, also known as lyophilization. Lyophilization is a dehydration technique that involves the removal of water or solvents from pharmaceutical products while preserving their structure and integrity. Vacuum pumps create a low-pressure environment in freeze drying chambers, allowing the frozen product to undergo sublimation. During sublimation, the frozen water or solvent directly transitions from the solid phase to the vapor phase, bypassing the liquid phase. Vacuum pumps facilitate efficient and controlled sublimation, leading to the production of stable, shelf-stable pharmaceutical products with extended shelf life.

5. Tablet and Capsule Manufacturing: Vacuum pumps are utilized in tablet and capsule manufacturing processes. They are involved in the creation of vacuum within tablet presses or capsule filling machines. By applying vacuum, the air is removed from the die cavity or capsule cavity, allowing for the precise filling of powders or granules. Vacuum pumps contribute to the production of uniform and well-formed tablets or capsules by ensuring accurate dosing and minimizing air entrapment, which can affect the final product quality.

6. Sterilization and Decontamination: Vacuum pumps are employed in sterilization and decontamination processes within the pharmaceutical industry. Autoclaves and sterilizers utilize vacuum pumps to create a vacuum environment before introducing steam or chemical sterilants. By removing air or gases from the chamber, vacuum pumps assist in achieving effective sterilization or decontamination by enhancing the penetration and distribution of sterilants. Vacuum pumps also aid in the removal of sterilants and residues after the sterilization process is complete.

It’s important to note that different types of vacuum pumps, such as rotary vane pumps, dry screw pumps, or liquid ring pumps, may be utilized in pharmaceutical manufacturing depending on the specific requirements of the process and the compatibility with pharmaceutical products.

In summary, vacuum pumps play a vital role in various stages of pharmaceutical manufacturing, including drying and evaporation, filtration and filtrate recovery, distillation and purification, freeze drying (lyophilization), tablet and capsule manufacturing, as well as sterilization and decontamination. By enabling efficient and controlled processes, vacuum pumps contribute to the production of high-quality pharmaceutical products, ensuring the desired characteristics, stability, and safety.

Can Vacuum Pumps Be Used in Laboratories?

Yes, vacuum pumps are extensively used in laboratories for a wide range of applications. Here’s a detailed explanation:

Vacuum pumps are essential tools in laboratory settings as they enable scientists and researchers to create and control vacuum or low-pressure environments. These controlled conditions are crucial for various scientific processes and experiments. Here are some key reasons why vacuum pumps are used in laboratories:

1. Evaporation and Distillation: Vacuum pumps are frequently used in laboratory evaporation and distillation processes. By creating a vacuum, they lower the boiling point of liquids, allowing for gentler and more controlled evaporation. This is particularly useful for heat-sensitive substances or when precise control over the evaporation process is required.

2. Filtration: Vacuum filtration is a common technique in laboratories for separating solids from liquids or gases. Vacuum pumps create suction, which helps draw the liquid or gas through the filter, leaving the solid particles behind. This method is widely used in processes such as sample preparation, microbiology, and analytical chemistry.

3. Freeze Drying: Vacuum pumps play a crucial role in freeze drying or lyophilization processes. Freeze drying involves removing moisture from a substance while it is in a frozen state, preserving its structure and properties. Vacuum pumps facilitate the sublimation of frozen water directly into vapor, resulting in the removal of moisture under low-pressure conditions.

4. Vacuum Ovens and Chambers: Vacuum pumps are used in conjunction with vacuum ovens and chambers to create controlled low-pressure environments for various applications. Vacuum ovens are used for drying heat-sensitive materials, removing solvents, or conducting reactions under reduced pressure. Vacuum chambers are utilized for testing components under simulated space or high-altitude conditions, degassing materials, or studying vacuum-related phenomena.

5. Analytical Instruments: Many laboratory analytical instruments rely on vacuum pumps to function properly. For example, mass spectrometers, electron microscopes, surface analysis equipment, and other analytical instruments often require vacuum conditions to maintain sample integrity and achieve accurate results.

6. Chemistry and Material Science: Vacuum pumps are employed in numerous chemical and material science experiments. They are used for degassing samples, creating controlled atmospheres, conducting reactions under reduced pressure, or studying gas-phase reactions. Vacuum pumps are also used in thin film deposition techniques like physical vapor deposition (PVD) and chemical vapor deposition (CVD).

7. Vacuum Systems for Experiments: In scientific research, vacuum systems are often designed and constructed for specific experiments or applications. These systems can include multiple vacuum pumps, valves, and chambers to create specialized vacuum environments tailored to the requirements of the experiment.

Overall, vacuum pumps are versatile tools that find extensive use in laboratories across various scientific disciplines. They enable researchers to control and manipulate vacuum or low-pressure conditions, facilitating a wide range of processes, experiments, and analyses. The choice of vacuum pump depends on factors such as required vacuum level, flow rate, chemical compatibility, and specific application needs.

editor by Dream 2024-05-17

China Professional 20m3/H Air Cooled Screw Vacuum Pump for Biological Medicine Food Chemical with Oilless No Oil and Clean Vacuum vacuum pump engine

Product Description

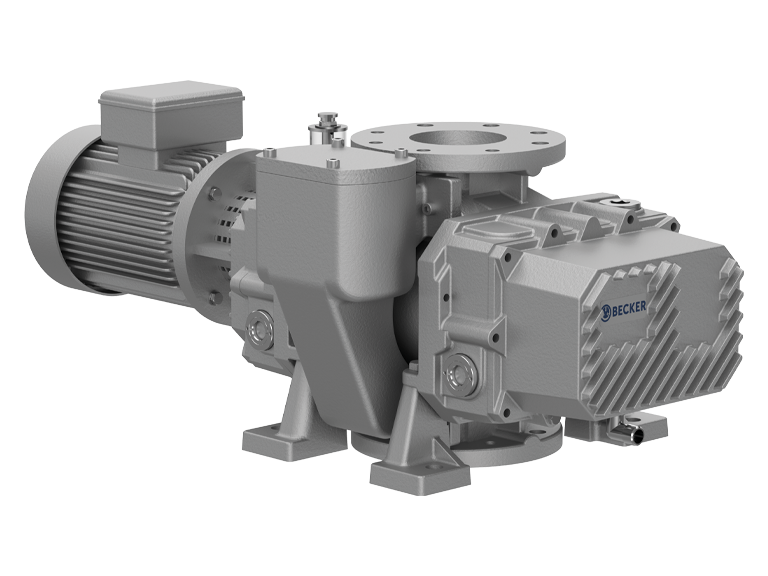

Dry Screw Vacuum Pump RSB571

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.

There is no medium in the working chamber, which can obtain a clean vacuum.

No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Product Parameters

| Product Model | 50/60Hz | RSB571 |

| Pumping Speed | 50Hz | 18m³/H |

| 60Hz | 22m³/H | |

| Ultimate Pressure | mbar | 0.03 |

| Inlet Diameter | KF40 | |

| Voltage | 50Hz | 200-240/345-415V |

| 60Hz | 220-275/380-480V | |

| Motor Power | kW | 1.5 |

| Rotate Speed | r/min | 2900/3500 |

| Noise Level | dB | 72 |

| Cooling Mode | Air Cooling | |

| Net Weight | kg | 48 |

Detailed Photos

Installation Instructions

Certifications

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Screw Number: | Double Screw Pump |

|---|---|

| Screw Suction Method: | Single Suction |

| Pump Shaft Position: | Horizontal |

| Performance: | Anticorrosion |

| Application: | Chemical |

| Certification: | CE, ISO |

| Samples: |

US$ 4500/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How Are Vacuum Pumps Employed in the Production of Electronic Components?

Vacuum pumps play a crucial role in the production of electronic components. Here’s a detailed explanation:

The production of electronic components often requires controlled environments with low or no atmospheric pressure. Vacuum pumps are employed in various stages of the production process to create and maintain these vacuum conditions. Here are some key ways in which vacuum pumps are used in the production of electronic components:

1. Deposition Processes: Vacuum pumps are extensively used in deposition processes, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), which are commonly employed for thin film deposition on electronic components. These processes involve the deposition of materials onto substrates in a vacuum chamber. Vacuum pumps help create and maintain the necessary vacuum conditions required for precise and controlled deposition of the thin films.

2. Etching and Cleaning: Etching and cleaning processes are essential in the fabrication of electronic components. Vacuum pumps are used to create a vacuum environment in etching and cleaning chambers, where reactive gases or plasmas are employed to remove unwanted materials or residues from the surfaces of the components. The vacuum pumps help evacuate the chamber and ensure the efficient removal of byproducts and waste gases.

3. Drying and Bake-out: Vacuum pumps are utilized in the drying and bake-out processes of electronic components. After wet processes, such as cleaning or wet etching, components need to be dried thoroughly. Vacuum pumps help create a vacuum environment that facilitates the removal of moisture or solvents from the components, ensuring their dryness before subsequent processing steps. Additionally, vacuum bake-out is employed to remove moisture or other contaminants trapped within the components’ materials or structures, enhancing their reliability and performance.

4. Encapsulation and Packaging: Vacuum pumps are involved in the encapsulation and packaging stages of electronic component production. These processes often require the use of vacuum-sealed packaging to protect the components from environmental factors such as moisture, dust, or oxidation. Vacuum pumps assist in evacuating the packaging materials, creating a vacuum-sealed environment that helps maintain the integrity and longevity of the electronic components.

5. Testing and Quality Control: Vacuum pumps are utilized in testing and quality control processes for electronic components. Some types of testing, such as hermeticity testing, require the creation of a vacuum environment for evaluating the sealing integrity of electronic packages. Vacuum pumps help evacuate the testing chambers, ensuring accurate and reliable test results.

6. Soldering and Brazing: Vacuum pumps play a role in soldering and brazing processes for joining electronic components and assemblies. Vacuum soldering is a technique used to achieve high-quality solder joints by removing air and reducing the risk of voids, flux residuals, or oxidation. Vacuum pumps assist in evacuating the soldering chambers, creating the required vacuum conditions for precise and reliable soldering or brazing.

7. Surface Treatment: Vacuum pumps are employed in surface treatment processes for electronic components. These processes include plasma cleaning, surface activation, or surface modification techniques. Vacuum pumps help create the necessary vacuum environment where plasma or reactive gases are used to treat the component surfaces, improving adhesion, promoting bonding, or altering surface properties.

It’s important to note that different types of vacuum pumps may be used in electronic component production, depending on the specific process requirements. Commonly used vacuum pump technologies include rotary vane pumps, turbo pumps, cryogenic pumps, and dry pumps.

In summary, vacuum pumps are essential in the production of electronic components, facilitating deposition processes, etching and cleaning operations, drying and bake-out stages, encapsulation and packaging, testing and quality control, soldering and brazing, as well as surface treatment. They enable the creation and maintenance of controlled vacuum environments, ensuring precise and reliable manufacturing processes for electronic components.

What Is the Role of Vacuum Pumps in Pharmaceutical Manufacturing?

Vacuum pumps play a crucial role in various aspects of pharmaceutical manufacturing. Here’s a detailed explanation:

Vacuum pumps are extensively used in pharmaceutical manufacturing processes to support a range of critical operations. Some of the key roles of vacuum pumps in pharmaceutical manufacturing include:

1. Drying and Evaporation: Vacuum pumps are employed in drying and evaporation processes within the pharmaceutical industry. They facilitate the removal of moisture or solvents from pharmaceutical products or intermediates. Vacuum drying chambers or evaporators utilize vacuum pumps to create low-pressure conditions, which lower the boiling points of liquids, allowing them to evaporate at lower temperatures. By applying vacuum, moisture or solvents can be efficiently removed from substances such as active pharmaceutical ingredients (APIs), granules, powders, or coatings, ensuring the desired product quality and stability.

2. Filtration and Filtrate Recovery: Vacuum pumps are used in filtration processes for the separation of solid-liquid mixtures. Vacuum filtration systems typically employ a filter medium, such as filter paper or membranes, to retain solids while allowing the liquid portion to pass through. By applying vacuum to the filtration apparatus, the liquid is drawn through the filter medium, leaving behind the solids. Vacuum pumps facilitate efficient filtration, speeding up the process and improving product quality. Additionally, vacuum pumps can aid in filtrate recovery by collecting and transferring the filtrate for further processing or reuse.

3. Distillation and Purification: Vacuum pumps are essential in distillation and purification processes within the pharmaceutical industry. Distillation involves the separation of liquid mixtures based on their different boiling points. By creating a vacuum environment, vacuum pumps lower the boiling points of the components, allowing them to vaporize and separate more easily. This enables efficient separation and purification of pharmaceutical compounds, including the removal of impurities or the isolation of specific components. Vacuum pumps are utilized in various distillation setups, such as rotary evaporators or thin film evaporators, to achieve precise control over the distillation conditions.

4. Freeze Drying (Lyophilization): Vacuum pumps are integral to the freeze drying process, also known as lyophilization. Lyophilization is a dehydration technique that involves the removal of water or solvents from pharmaceutical products while preserving their structure and integrity. Vacuum pumps create a low-pressure environment in freeze drying chambers, allowing the frozen product to undergo sublimation. During sublimation, the frozen water or solvent directly transitions from the solid phase to the vapor phase, bypassing the liquid phase. Vacuum pumps facilitate efficient and controlled sublimation, leading to the production of stable, shelf-stable pharmaceutical products with extended shelf life.

5. Tablet and Capsule Manufacturing: Vacuum pumps are utilized in tablet and capsule manufacturing processes. They are involved in the creation of vacuum within tablet presses or capsule filling machines. By applying vacuum, the air is removed from the die cavity or capsule cavity, allowing for the precise filling of powders or granules. Vacuum pumps contribute to the production of uniform and well-formed tablets or capsules by ensuring accurate dosing and minimizing air entrapment, which can affect the final product quality.

6. Sterilization and Decontamination: Vacuum pumps are employed in sterilization and decontamination processes within the pharmaceutical industry. Autoclaves and sterilizers utilize vacuum pumps to create a vacuum environment before introducing steam or chemical sterilants. By removing air or gases from the chamber, vacuum pumps assist in achieving effective sterilization or decontamination by enhancing the penetration and distribution of sterilants. Vacuum pumps also aid in the removal of sterilants and residues after the sterilization process is complete.

It’s important to note that different types of vacuum pumps, such as rotary vane pumps, dry screw pumps, or liquid ring pumps, may be utilized in pharmaceutical manufacturing depending on the specific requirements of the process and the compatibility with pharmaceutical products.

In summary, vacuum pumps play a vital role in various stages of pharmaceutical manufacturing, including drying and evaporation, filtration and filtrate recovery, distillation and purification, freeze drying (lyophilization), tablet and capsule manufacturing, as well as sterilization and decontamination. By enabling efficient and controlled processes, vacuum pumps contribute to the production of high-quality pharmaceutical products, ensuring the desired characteristics, stability, and safety.

What Are the Primary Applications of Vacuum Pumps?

Vacuum pumps have a wide range of applications across various industries. Here’s a detailed explanation:

1. Industrial Processes:

Vacuum pumps play a vital role in numerous industrial processes, including:

– Vacuum Distillation: Vacuum pumps are used in distillation processes to lower the boiling points of substances, enabling separation and purification of various chemicals and compounds.

– Vacuum Drying: Vacuum pumps aid in drying processes by creating a low-pressure environment, which accelerates moisture removal from materials without excessive heat.

– Vacuum Packaging: Vacuum pumps are used in the food industry to remove air from packaging containers, prolonging the shelf life of perishable goods by reducing oxygen exposure.

– Vacuum Filtration: Filtration processes can benefit from vacuum pumps to enhance filtration rates by applying suction, facilitating faster separation of solids and liquids.

2. Laboratory and Research:

Vacuum pumps are extensively used in laboratories and research facilities for various applications:

– Vacuum Chambers: Vacuum pumps create controlled low-pressure environments within chambers for conducting experiments, testing materials, or simulating specific conditions.

– Mass Spectrometry: Mass spectrometers often utilize vacuum pumps to create the necessary vacuum conditions for ionization and analysis of samples.

– Freeze Drying: Vacuum pumps enable freeze-drying processes, where samples are frozen and then subjected to a vacuum, allowing the frozen water to sublimate directly from solid to vapor state.

– Electron Microscopy: Vacuum pumps are essential for electron microscopy techniques, providing the necessary vacuum environment for high-resolution imaging of samples.

3. Semiconductor and Electronics Industries:

High vacuum pumps are critical in the semiconductor and electronics industries for manufacturing and testing processes:

– Semiconductor Fabrication: Vacuum pumps are used in various stages of chip manufacturing, including deposition, etching, and ion implantation processes.

– Thin Film Deposition: Vacuum pumps create the required vacuum conditions for depositing thin films of materials onto substrates, as done in the production of solar panels, optical coatings, and electronic components.

– Leak Detection: Vacuum pumps are utilized in leak testing applications to detect and locate leaks in electronic components, systems, or pipelines.

4. Medical and Healthcare:

Vacuum pumps have several applications in the medical and healthcare sectors:

– Vacuum Assisted Wound Closure: Vacuum pumps are used in negative pressure wound therapy (NPWT), where they create a controlled vacuum environment to promote wound healing and removal of excess fluids.

– Laboratory Equipment: Vacuum pumps are essential in medical and scientific equipment such as vacuum ovens, freeze dryers, and centrifugal concentrators.

– Anesthesia and Medical Suction: Vacuum pumps are utilized in anesthesia machines and medical suction devices to create suction and remove fluids or gases from the patient’s body.

5. HVAC and Refrigeration:

Vacuum pumps are employed in the HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries:

– Refrigeration and Air Conditioning Systems: Vacuum pumps are used during system installation, maintenance, and repair to evacuate moisture and air from refrigeration and air conditioning systems, ensuring efficient operation.

– Vacuum Insulation Panels: Vacuum pumps are utilized in the manufacturing of vacuum insulation panels, which offer superior insulation properties for buildings and appliances.

6. Power Generation:

Vacuum pumps play a role in power generation applications:

– Steam Condenser Systems: Vacuum pumps are used in power plants to remove non-condensable gases from steam condenser systems, improving thermal efficiency.

– Gas Capture: Vacuum pumps are utilized to capture and remove gases, such as hydrogen or helium, in nuclear power plants, research reactors, or particle accelerators.

These are just a few examples of the primary applications of vacuum pumps. The versatility and wide range of vacuum pump types make them essential in numerous industries, contributing to various manufacturing processes, research endeavors, and technological advancements.

editor by Dream 2024-05-09

China Hot selling Customized 0.75kw Power Electric Roots Vacuum Air Pump for Industrial Boilers vacuum pump

Product Description

Customized 0.75kw Power Electric Roots Vacuum Air Pump for Industrial Boilers

Product Description

Product Parameters

|

Model |

ZJ-30 |

ZJ-70 |

ZJ-150 |

ZJ-300 |

ZJ-600 |

ZJ-1200 |

ZJ-2500 |

ZJ-5000 |

|

Ultimate total pressure(Pa) |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

|

Motor Power(Kw) |

0.75 |

1.5 |

3 |

4 |

7.5 |

11 |

22 |

45 |

|

Nominal Motor speed(rpm) |

2850 |

2850 |

2870 |

1450 |

2900 |

1400 |

2880 |

1450 |

|

Nominal Motor current(A) |

1.8 |

3.4 |

6.2 |

15.4 |

14.8 |

22.3 |

41 |

84.7 |

|

Pumping size(mm) |

650X315X255 |

770X315X255 |

1060X462X380 |

1330X556X505 |

1410X556X505 |

1710X1070X850 |

1820X1070X850 |

2700X1200X1100 |

|

Weight (with oil filling)kg |

76 |

96 |

200 |

502 |

520 |

1550 |

1620 |

4000 |

|

Type of protection(IP) |

55 |

55 |

55 |

55 |

55 |

55 |

55 |

55 |

Detailed Photos

Roots vacuum pump (abbreviated as Roots pump) is a rotary variable capacity vacuum pump without internal compression. It utilizes 2 8-shaped rotors to rotate in the pump casing to generate suction and exhaust effects. Its principle is similar to that of a Roots blower. Due to its operation in a low pressure range, the gas molecules have a large free range, and the resistance of gas leakage through small slits is high, so it can achieve a high compression ratio and can be used as a booster vacuum pump; But it cannot directly discharge the gas into the atmosphere alone, and needs to be used in series with the front stage vacuum pump. The extracted gas is carried into the atmosphere through the front stage vacuum pump.

Roots pumps are widely used in vacuum degassing, vacuum melting, vacuum treatment of molten steel in the vacuum metallurgy industry, as well as in devices such as space simulation and low-density wind tunnels to extract corrosive gases. It can also be used in production processes such as distillation, evaporation, and drying in industries such as chemical, food, pharmaceutical, and motor manufacturing.

The ZJ series Roots vacuum pump is a rotary variable capacity vacuum pump that requires a front stage pump to be used. It has a large pumping speed in a wide pressure range in China and is not sensitive to dust and water vapor in the extracted gas. It is widely used in industries such as metallurgy, chemical industry, food, and electronic coating.

Company Profile

HangZhou Sifang Vacuum Equipment Co., Ltd. specializes in the production of vacuum furnaces, vacuum pumps, steel drums and other products.”Sifang” is the registered trademark of the company’s products.

our company is 1 professional vacuum equipment manufacturer in HangZhou, China. We specialize in vacuum pumps, furnaces, systems and components for diverse applications. We produce rotary vane vacuum pumps, water ring vacuum pumps, reciprocating vacuum pumps, roots vacuum pump units, vacuum heat treatment furnaces, vacuum aluminum brazing furnaces, high temperature brazing fur- naces, vacuum sintering furnaces, monocrystalline silicon furnaces and other products. All these vacuum equipment are widely used in aviation, aerospace, military, railway, automobile, machinery, mold, electronics, metallurgy, scientific research and other fields.

We have professional engineer support, high efficiency sales team and competitive price superiority, and attract customers from all over the world, we export to over 40 countries, including Europe, Poland, Serbia, Turkey, Russia, USA, Mexico, Brazil, India, Thailand, Middle east and South Africa.

After several years’ development, We have achieved great progress, we are equipped with the AutomaticCNCmachines and multi-func- tion testing machines. Our R&D department provide the strong tech- nical support and enable us to receive some 0 E M, O D M projects. We can produce at least 3000 sets vacuum equipment per year. With our innovative and energy-efficient vacuum equipment that is put to work in a multitude of manufacturing and process applica- tions, we also offer you a comprehensive suite of CHINAMFG ser- vices to complement our products.

FAQ

1.Q: Are you a factory or trading company?

A: We are a factory and we have professional team of workers,Designers and inspectors.

2.Q:Do you accept custom?

A:Of course.We have professional teams who make your designs,photos,imagines and OEM orders into real production.

3.Q:What’s your advantages?

A: Quick response to your enquiry,

High quality control,

Reasonable price,

Timely delivery,

Excellent after-sales service,

OEM/ODM are welcome

4.Q:What’s your shipping terms?

A:If you need to ship by air,we can use DHL,UPS,FedEx,TNT or EMS.If you need to ship by sea,we have many good forwarders to work with,they can provide the best price for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Support |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil |

| Structure: | Vacuum Pump |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | Vacuum |

| Customization: |

Available

|

|

|---|

How Are Roots Vacuum Pumps Utilized in the Automotive Industry?

Roots vacuum pumps play a significant role in various applications within the automotive industry. Here’s a detailed explanation:

1. Brake System Vacuum Pumps:

– Vacuum Boosters: Roots vacuum pumps are commonly used as vacuum boosters in automotive brake systems. They assist in enhancing the braking performance by providing the necessary vacuum for power brake operation. When the driver applies the brake pedal, the vacuum booster uses the suction power generated by the Roots pump to amplify the force applied to the brake master cylinder, resulting in more effective braking.

– Electric Brake Vacuum Pumps: In modern electric or hybrid vehicles, where traditional engine-driven vacuum sources may not be available, electric brake vacuum pumps are utilized. These pumps, often based on the Roots principle, generate vacuum independently to power the brake booster and ensure reliable braking performance.

2. Emissions Control:

– Evaporative Emission Control: Roots vacuum pumps are employed in evaporative emission control systems to prevent the release of harmful vapors from the fuel system into the atmosphere. These pumps create a vacuum within the system, purging and storing fuel vapors in a canister for subsequent combustion or recycling.

– Positive Crankcase Ventilation (PCV): PCV systems, which are designed to reduce emissions and maintain the integrity of the engine, also utilize Roots vacuum pumps. These pumps draw crankcase gases and vapors, including oil mist, from the engine’s crankcase into the intake manifold for combustion, improving overall engine efficiency and reducing pollution.

3. Engine Testing and Development:

– Vacuum Leakage Testing: Roots vacuum pumps are utilized for vacuum leakage testing in engine manufacturing and development. By creating a vacuum in the intake manifold or other engine components, these pumps enable the detection of leaks and ensure the integrity of the engine’s air delivery system.

– Air Flow Calibration: During engine testing and calibration, Roots vacuum pumps are used to simulate various operating conditions by controlling the intake air flow. This allows engineers to fine-tune the engine’s performance, optimize fuel-air mixture ratios, and assess the engine’s efficiency and emissions characteristics.

4. HVAC Systems:

– Climate Control: Roots vacuum pumps are employed in automotive HVAC (Heating, Ventilation, and Air Conditioning) systems to facilitate the flow and distribution of air. These pumps help regulate the operation of HVAC components, such as air blend doors and vacuum actuators, ensuring proper air temperature and direction control inside the vehicle cabin.

5. Fuel System and Turbocharging:

– Fuel Transfer and Evacuation: In automotive fuel systems, Roots vacuum pumps are used for fuel transfer and evacuation. These pumps assist in priming the fuel system, removing air pockets, and ensuring the continuous flow of fuel to the engine, enhancing the overall fuel delivery performance.

– Turbocharger Control: Roots vacuum pumps are sometimes employed in turbocharged engines to control the actuation of variable geometry turbochargers (VGT). These pumps provide the necessary vacuum signals to actuate the VGT mechanism, optimizing turbocharger performance and enhancing engine efficiency.

6. Other Applications:

– Electric Vehicle Battery Systems: In electric vehicles, Roots vacuum pumps are utilized to create a vacuum in battery enclosures, helping to maintain the integrity and safety of the battery system by preventing the ingress of moisture, dust, or contaminants.

– Engine Air Induction: Some automotive engines utilize Roots-type superchargers or twin-screw superchargers, which are essentially positive displacement Roots vacuum pumps operating in reverse. These devices compress and force air into the engine’s intake manifold, resulting in increased engine power and performance.

In summary, Roots vacuum pumps find extensive utilization in the automotive industry. They play a crucial role in brake systems, emissions control, engine testing and development, HVAC systems, fuel systems, turbocharging, electric vehicle battery systems, and engine air induction. By contributing to braking performance, emissions reduction, engine calibration, HVAC functionality, fuel system efficiency, turbocharger control, battery system safety, and engine power enhancement, Roots vacuum pumps contribute significantly to the overall operation and performance of automotive systems and components.

What Is a Roots Vacuum Pump, and How Does It Work?

A Roots vacuum pump, also known as a Roots blower or a rotary lobe pump, is a type of positive displacement vacuum pump that is widely used for various industrial applications. Here’s a detailed explanation of what a Roots vacuum pump is and how it works:

A Roots vacuum pump consists of two synchronized rotors, known as lobes or impellers, that rotate in opposite directions within a housing. The lobes have a unique helical shape with multiple lobes, which allows them to trap and move gas efficiently. The rotors are synchronized with the help of timing gears to maintain precise clearances between the lobes and the housing.

The operation of a Roots vacuum pump can be described in the following steps:

1. Inlet Stage: The process begins with the lobes rotating in opposite directions. As the lobes rotate, the volume between them and the housing gradually increases, creating a larger space at the inlet side of the pump. This expansion of the volume causes the gas to enter the pump through the inlet port. The gas is drawn in due to the pressure difference between the inlet and the pump’s internal chamber.

2. Compression Stage: As the gas enters the pump, it gets trapped in the spaces between the lobes and the housing. As the lobes continue to rotate, the trapped gas gets carried along the rotating lobes. The gas is essentially trapped in the pockets formed by the lobes and the housing. The rotating lobes then compress the gas as they move towards the outlet side of the pump.

3. Outlet Stage: As the lobes approach the outlet side of the pump, the volume between them and the housing decreases, resulting in the compression of the trapped gas. This compression raises the pressure of the gas, causing it to be expelled through the outlet port of the pump. The expelled gas is then discharged into the atmosphere or directed to a downstream process or another vacuum pump, depending on the application.

It’s important to note that a Roots vacuum pump operates as a non-contacting pump, meaning that there is no physical contact between the lobes or between the lobes and the housing. This characteristic eliminates the need for lubrication within the pump and reduces the risk of contamination or oil vapor backstreaming into the vacuum system.

Roots vacuum pumps are known for their high pumping speed and ability to handle large volumes of gas. However, they are not capable of achieving high vacuum levels on their own. To achieve higher vacuum levels, a Roots pump is often used in conjunction with other vacuum pumps, such as rotary vane pumps or diffusion pumps, in a hybrid or combination pumping system.

In summary, a Roots vacuum pump operates based on the principle of positive displacement. It utilizes synchronized rotating lobes to trap and compress gas, allowing it to be discharged at a higher pressure. The non-contacting design of the pump eliminates the need for lubrication and reduces the risk of contamination. Roots vacuum pumps are commonly employed in various industrial applications, especially when high pumping speed and large gas handling capacity are required.

editor by Dream 2024-05-09

China factory China Vacuum Air Solids Pump/Wast/Slurry /Sewage/Slush/Mud Pump for Sale vacuum pump belt

Product Description

The Pneumatic dredging and seage pumps (namly Portable Slurry Vacuum Pump) is 1 kind 100% air powered and operated material transferring equipment. It generates Vacuum combined with high airflow which allows the unit to transfer materials ranging from mining slurries and oil sludge through to cement powders and grains etc. It is also known as sludge pump, mud pump, Solids Pump, Waste transfer Pump etc.

The Portable Slurry Vacuum Pump is widely used in farms, mines, drill rigs, municipal, industrial and construction sites.

| Model | Flow | Discharge | Air consumption | Working pressure | Installation dimensions | Weight (kg) |

|

| m³/h | m | m³/min | MPa | (Length × width × height) mm | |||

| QYF25-15 | 25 | 15 | 11 | 0.5 | 1830×885×965 | 315 | |

| QYF20-20 | 20 | 20 | 10.5 | 0.5 | 1830×834×915 | 285 | |

| QYF17-20 | 17 | 20 | 8.5 | 0.5 | 1830×782×890 | 260 | |

| QYF14-20 | 14 | 20 | 6.5 | 0.5 | 1830×782×890 | 255 | |

| QYF10-20 | 10 | 20 | 6 | 0.5 | 1830×782×890 | 250 | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service |

|---|---|

| Warranty: | 1 Year |

| Type: | Vacuum Pump |

| Air Engine Type: | Pneumatic Power |

| Theory: | Venturi Principle |

| Transmission: | Direct Connection Transmission |

| Samples: |

US$ 5500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used in the Aerospace Sector?

Vacuum pumps indeed have various applications in the aerospace sector. Here’s a detailed explanation:

Vacuum pumps play a crucial role in several areas of the aerospace industry, supporting various processes and systems. Some of the key applications of vacuum pumps in the aerospace sector include:

1. Space Simulation Chambers: Vacuum pumps are used in space simulation chambers to replicate the low-pressure conditions experienced in outer space. These chambers are utilized for testing and validating the performance and functionality of aerospace components and systems under simulated space conditions. Vacuum pumps create and maintain the necessary vacuum environment within these chambers, allowing engineers and scientists to evaluate the behavior and response of aerospace equipment in space-like conditions.

2. Propellant Management: In space propulsion systems, vacuum pumps are employed for propellant management. They help in the transfer, circulation, and pressurization of propellants, such as liquid rocket fuels or cryogenic fluids, in both launch vehicles and spacecraft. Vacuum pumps assist in creating the required pressure differentials for propellant flow and control, ensuring efficient and reliable operation of propulsion systems.

3. Environmental Control Systems: Vacuum pumps are utilized in the environmental control systems of aircraft and spacecraft. These systems are responsible for maintaining the desired atmospheric conditions, including temperature, humidity, and cabin pressure, to ensure the comfort, safety, and well-being of crew members and passengers. Vacuum pumps are used to regulate and control the cabin pressure, facilitating the circulation of fresh air and maintaining the desired air quality within the aircraft or spacecraft.

4. Satellite Technology: Vacuum pumps find numerous applications in satellite technology. They are used in the fabrication and testing of satellite components, such as sensors, detectors, and electronic devices. Vacuum pumps help create the necessary vacuum conditions for thin film deposition, surface treatment, and testing processes, ensuring the performance and reliability of satellite equipment. Additionally, vacuum pumps are employed in satellite propulsion systems to manage propellants and provide thrust for orbital maneuvers.

5. Avionics and Instrumentation: Vacuum pumps are involved in the production and testing of avionics and instrumentation systems used in aerospace applications. They facilitate processes such as thin film deposition, vacuum encapsulation, and vacuum drying, ensuring the integrity and functionality of electronic components and circuitry. Vacuum pumps are also utilized in vacuum leak testing, where they help create a vacuum environment to detect and locate any leaks in aerospace systems and components.

6. High Altitude Testing: Vacuum pumps are used in high altitude testing facilities to simulate the low-pressure conditions encountered at high altitudes. These testing facilities are employed for evaluating the performance and functionality of aerospace equipment, such as engines, materials, and structures, under simulated high altitude conditions. Vacuum pumps create and control the required low-pressure environment, allowing engineers and researchers to assess the behavior and response of aerospace systems in high altitude scenarios.

7. Rocket Engine Testing: Vacuum pumps are crucial in rocket engine testing facilities. They are utilized to evacuate and maintain the vacuum conditions in engine test chambers or nozzles during rocket engine testing. By creating a vacuum environment, these pumps simulate the conditions experienced by rocket engines in the vacuum of space, enabling accurate testing and evaluation of engine performance, thrust levels, and efficiency.

It’s important to note that aerospace applications often require specialized vacuum pumps capable of meeting stringent requirements, such as high reliability, low outgassing, compatibility with propellants or cryogenic fluids, and resistance to extreme temperatures and pressures.

In summary, vacuum pumps are extensively used in the aerospace sector for a wide range of applications, including space simulation chambers, propellant management, environmental control systems, satellite technology, avionics and instrumentation, high altitude testing, and rocket engine testing. They contribute to the development, testing, and operation of aerospace equipment, ensuring optimal performance, reliability, and safety.

Can Vacuum Pumps Be Used in the Production of Solar Panels?

Yes, vacuum pumps are extensively used in the production of solar panels. Here’s a detailed explanation:

Solar panels, also known as photovoltaic (PV) panels, are devices that convert sunlight into electricity. The manufacturing process of solar panels involves several critical steps, many of which require the use of vacuum pumps. Vacuum technology plays a crucial role in ensuring the efficiency, reliability, and quality of solar panel production. Here are some key areas where vacuum pumps are utilized:

1. Silicon Ingot Production: The first step in solar panel manufacturing is the production of silicon ingots. These ingots are cylindrical blocks of pure crystalline silicon that serve as the raw material for solar cells. Vacuum pumps are used in the Czochralski process, which involves melting polycrystalline silicon in a quartz crucible and then slowly pulling a single crystal ingot from the molten silicon. Vacuum pumps create a controlled environment by removing impurities and preventing contamination during the crystal growth process.

2. Wafering: After the silicon ingots are produced, they undergo wafering, where the ingots are sliced into thin wafers. Vacuum pumps are used in wire saws to create a low-pressure environment that helps to cool and lubricate the cutting wire. The vacuum also assists in removing the silicon debris generated during the slicing process, ensuring clean and precise cuts.

3. Solar Cell Production: Vacuum pumps play a significant role in various stages of solar cell production. Solar cells are the individual units within a solar panel that convert sunlight into electricity. Vacuum pumps are used in the following processes:

– Diffusion: In the diffusion process, dopants such as phosphorus or boron are introduced into the silicon wafer to create the desired electrical properties. Vacuum pumps are utilized in the diffusion furnace to create a controlled atmosphere for the diffusion process and remove any impurities or gases that may affect the quality of the solar cell.

– Deposition: Thin films of materials such as anti-reflective coatings, passivation layers, and electrode materials are deposited onto the silicon wafer. Vacuum pumps are used in various deposition techniques like physical vapor deposition (PVD) or chemical vapor deposition (CVD) to create the necessary vacuum conditions for precise and uniform film deposition.

– Etching: Etching processes are employed to create the desired surface textures on the solar cell, which enhance light trapping and improve efficiency. Vacuum pumps are used in plasma etching or wet etching techniques to remove unwanted material or create specific surface structures on the solar cell.

4. Encapsulation: After the solar cells are produced, they are encapsulated to protect them from environmental factors such as moisture and mechanical stress. Vacuum pumps are used in the encapsulation process to create a vacuum environment, ensuring the removal of air and moisture from the encapsulation materials. This helps to achieve proper bonding and prevents the formation of bubbles or voids, which could degrade the performance and longevity of the solar panel.

5. Testing and Quality Control: Vacuum pumps are also utilized in testing and quality control processes during solar panel production. For example, vacuum systems can be used for leak testing to ensure the integrity of the encapsulation and to detect any potential defects or leaks in the panel assembly. Vacuum-based measurement techniques may also be employed for assessing the electrical characteristics and efficiency of the solar cells or panels.

In summary, vacuum pumps are integral to the production of solar panels. They are used in various stages of the manufacturing process, including silicon ingot production, wafering, solar cell production (diffusion, deposition, and etching), encapsulation, and testing. Vacuum technology enables precise control, contamination prevention, and efficient processing, contributing to the production of high-quality and reliable solar panels.

What Is the Purpose of a Vacuum Pump in an HVAC System?

In an HVAC (Heating, Ventilation, and Air Conditioning) system, a vacuum pump serves a crucial purpose. Here’s a detailed explanation:

The purpose of a vacuum pump in an HVAC system is to remove air and moisture from the refrigerant lines and the system itself. HVAC systems, particularly those that rely on refrigeration, operate under specific pressure and temperature conditions to facilitate the transfer of heat. To ensure optimal performance and efficiency, it is essential to evacuate any non-condensable gases, air, and moisture from the system.

Here are the key reasons why a vacuum pump is used in an HVAC system:

1. Removing Moisture: Moisture can be present within an HVAC system due to various factors, such as system installation, leaks, or improper maintenance. When moisture combines with the refrigerant, it can cause issues like ice formation, reduced system efficiency, and potential damage to system components. A vacuum pump helps remove moisture by creating a low-pressure environment, which causes the moisture to boil and turn into vapor, effectively evacuating it from the system.

2. Eliminating Air and Non-Condensable Gases: Air and non-condensable gases, such as nitrogen or oxygen, can enter an HVAC system during installation, repair, or through leaks. These gases can hinder the refrigeration process, affect heat transfer, and decrease system performance. By using a vacuum pump, technicians can evacuate the air and non-condensable gases, ensuring that the system operates with the designed refrigerant and pressure levels.

3. Preparing for Refrigerant Charging: Prior to charging the HVAC system with refrigerant, it is crucial to create a vacuum to remove any contaminants and ensure the system is clean and ready for optimal refrigerant circulation. By evacuating the system with a vacuum pump, technicians ensure that the refrigerant enters a clean and controlled environment, reducing the risk of system malfunctions and improving overall efficiency.

4. Leak Detection: Vacuum pumps are also used in HVAC systems for leak detection purposes. After evacuating the system, technicians can monitor the pressure to check if it holds steady. A significant drop in pressure indicates the presence of leaks, enabling technicians to identify and repair them before charging the system with refrigerant.

In summary, a vacuum pump plays a vital role in an HVAC system by removing moisture, eliminating air and non-condensable gases, preparing the system for refrigerant charging, and aiding in leak detection. These functions help ensure optimal system performance, energy efficiency, and longevity, while also reducing the risk of system malfunctions and damage.

editor by Dream 2024-05-06

China Standard Vakuum Pumpe Air Rotary Roots Liquid-Ring Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps vacuum pump for ac

Product Description

Vakuum Pumpe Air Rotary Roots Liquid-Ring Water Piston Dry Portable Mini Scroll Reciprocating Diaphragm Centrifugal Positive Displacement DC AC Vacuum Pumps

VP roots vacuum pump is in the 50 Torr-micron high vacuum range has a large pumping speed and low cost of equipment, it can be combined with various vacuum pump consists of a vacuum unit. KMBD roots vacuum pump with 5 point bearing design unique, sealing the five bit machine, sealing double sealing structure + mechanical seal for Teflon maze, can realize non leakage, reduce maintenance and repair of the link, ensure the roots pump and durable. Synchronous helical gear and mounted on the driving end, both to ensure quiet and reliable operation, and can reduce the load of the rotor torque. Impeller and shaft integrally cast, can provide large size shaft, impeller and reduce the risk of damage. All contact with the sealing surface of the shaft end faces are polished to reduce wear and reduce the risk of leakage, high temperature high pressure casing, and double tank design, a variety of material selection, further to ensure that the use of the user in various working conditions. Typical application: chemical, petrochemical, plastics, semiconductors, wood mixture, food processing, vacuum furnace, vacuum booster system, vacuum drying, vacuum dewatering, vacuum packaging

Typical Applications

Special structures working principles,suitable for operation in chemical industry,oil industry,food industry,electrical utility industry,pharmacy industry,textile industry and paper making industry,etc. The other industries that need vacuum drying,concentration,distilling,dehydration and filtering also need the water-ring vacuum pump. It can be use as a backing pump of Roots Pump.

Specifications

| Model | Capacity | Ultimate Pressure | Power | speed |

| L/S | Pa | KW | RPM | |

| VP200 | 200 | 0.05 | 4 | 2900 |

| VP600 | 600 | 0.05 | 7.5 | 2900 |

Characteristic Curves

Overall Dimensions

company information

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Oil or Not: | Optional |

|---|---|

| Inlet Diam. (mm): | 100/200mm |

| Motor Power (Kw): | 4/7.5 Kw |

| Ultimate Pressure (PA): | 0.05 |

| Transport Package: | Wooden Case |

| Trademark: | OEM |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

How Are Roots Vacuum Pumps Utilized in the Automotive Industry?

Roots vacuum pumps play a significant role in various applications within the automotive industry. Here’s a detailed explanation:

1. Brake System Vacuum Pumps:

– Vacuum Boosters: Roots vacuum pumps are commonly used as vacuum boosters in automotive brake systems. They assist in enhancing the braking performance by providing the necessary vacuum for power brake operation. When the driver applies the brake pedal, the vacuum booster uses the suction power generated by the Roots pump to amplify the force applied to the brake master cylinder, resulting in more effective braking.

– Electric Brake Vacuum Pumps: In modern electric or hybrid vehicles, where traditional engine-driven vacuum sources may not be available, electric brake vacuum pumps are utilized. These pumps, often based on the Roots principle, generate vacuum independently to power the brake booster and ensure reliable braking performance.

2. Emissions Control:

– Evaporative Emission Control: Roots vacuum pumps are employed in evaporative emission control systems to prevent the release of harmful vapors from the fuel system into the atmosphere. These pumps create a vacuum within the system, purging and storing fuel vapors in a canister for subsequent combustion or recycling.

– Positive Crankcase Ventilation (PCV): PCV systems, which are designed to reduce emissions and maintain the integrity of the engine, also utilize Roots vacuum pumps. These pumps draw crankcase gases and vapors, including oil mist, from the engine’s crankcase into the intake manifold for combustion, improving overall engine efficiency and reducing pollution.

3. Engine Testing and Development:

– Vacuum Leakage Testing: Roots vacuum pumps are utilized for vacuum leakage testing in engine manufacturing and development. By creating a vacuum in the intake manifold or other engine components, these pumps enable the detection of leaks and ensure the integrity of the engine’s air delivery system.

– Air Flow Calibration: During engine testing and calibration, Roots vacuum pumps are used to simulate various operating conditions by controlling the intake air flow. This allows engineers to fine-tune the engine’s performance, optimize fuel-air mixture ratios, and assess the engine’s efficiency and emissions characteristics.

4. HVAC Systems:

– Climate Control: Roots vacuum pumps are employed in automotive HVAC (Heating, Ventilation, and Air Conditioning) systems to facilitate the flow and distribution of air. These pumps help regulate the operation of HVAC components, such as air blend doors and vacuum actuators, ensuring proper air temperature and direction control inside the vehicle cabin.

5. Fuel System and Turbocharging:

– Fuel Transfer and Evacuation: In automotive fuel systems, Roots vacuum pumps are used for fuel transfer and evacuation. These pumps assist in priming the fuel system, removing air pockets, and ensuring the continuous flow of fuel to the engine, enhancing the overall fuel delivery performance.

– Turbocharger Control: Roots vacuum pumps are sometimes employed in turbocharged engines to control the actuation of variable geometry turbochargers (VGT). These pumps provide the necessary vacuum signals to actuate the VGT mechanism, optimizing turbocharger performance and enhancing engine efficiency.

6. Other Applications:

– Electric Vehicle Battery Systems: In electric vehicles, Roots vacuum pumps are utilized to create a vacuum in battery enclosures, helping to maintain the integrity and safety of the battery system by preventing the ingress of moisture, dust, or contaminants.

– Engine Air Induction: Some automotive engines utilize Roots-type superchargers or twin-screw superchargers, which are essentially positive displacement Roots vacuum pumps operating in reverse. These devices compress and force air into the engine’s intake manifold, resulting in increased engine power and performance.

In summary, Roots vacuum pumps find extensive utilization in the automotive industry. They play a crucial role in brake systems, emissions control, engine testing and development, HVAC systems, fuel systems, turbocharging, electric vehicle battery systems, and engine air induction. By contributing to braking performance, emissions reduction, engine calibration, HVAC functionality, fuel system efficiency, turbocharger control, battery system safety, and engine power enhancement, Roots vacuum pumps contribute significantly to the overall operation and performance of automotive systems and components.

What Are the Advantages of Using Roots Vacuum Pumps?

Roots vacuum pumps, also known as Roots blowers or rotary lobe pumps, offer several advantages that make them a popular choice for various industrial applications. Here’s a detailed explanation of the advantages of using Roots vacuum pumps:

1. High Pumping Speed: Roots vacuum pumps are known for their high pumping speed, which refers to the rate at which they can remove gas from a vacuum system. The unique design of synchronized rotating lobes enables these pumps to handle large volumes of gas efficiently. This high pumping speed makes Roots vacuum pumps well-suited for applications that require rapid evacuation or continuous extraction of gases.

2. Large Gas Handling Capacity: Roots vacuum pumps have a large gas handling capacity, allowing them to handle a wide range of gases, including clean air, corrosive gases, and vapors. Their robust construction and ability to handle gas with particulates or liquids make them suitable for applications in industries such as chemical processing, pharmaceuticals, food processing, and wastewater treatment.

3. Oil-Free and Contamination-Free Operation: One of the significant advantages of Roots vacuum pumps is that they operate without the need for lubrication. The non-contacting design of the pump eliminates the risk of oil contamination in the vacuum system. This is particularly important in applications where clean, oil-free vacuum environments are required, such as semiconductor manufacturing, electronics, and research laboratories.

4. Reliable and Low Maintenance: Roots vacuum pumps are known for their reliability and low maintenance requirements. Since there is no lubrication or contact between the lobes, there is minimal wear and tear, reducing the need for frequent maintenance or replacement of parts. This results in reduced downtime and lower operating costs for the users.

5. Noise and Vibration Reduction: Roots vacuum pumps are designed to operate with low noise and vibration levels. The precision engineering and balanced rotation of the lobes help minimize noise generation and vibration transmission. This makes Roots vacuum pumps suitable for applications where noise reduction and vibration control are important, such as in laboratories, medical facilities, and residential areas.

6. Wide Range of Vacuum Levels: While Roots vacuum pumps are not capable of achieving high vacuum levels on their own, they can be combined with other vacuum pumps, such as rotary vane pumps or diffusion pumps, to create hybrid or combination pumping systems. This allows them to cover a wide range of vacuum levels, making them versatile and adaptable to different application requirements.

7. Energy Efficiency: Roots vacuum pumps are designed to be energy-efficient, offering a favorable power-to-pumping speed ratio. Their efficient design and minimal internal losses help reduce energy consumption, resulting in lower operating costs for the users. This makes them an economical choice for continuous or high-throughput processes that require significant vacuum power.

8. Versatility and Compatibility: Roots vacuum pumps are compatible with various gases and can be used in a wide range of industrial applications. They find applications in industries such as chemical processing, pharmaceuticals, food processing, automotive, packaging, and environmental technology. Their versatility and compatibility make them suitable for both rough vacuum applications and as part of complex vacuum systems.

In summary, the advantages of using Roots vacuum pumps include high pumping speed, large gas handling capacity, oil-free and contamination-free operation, reliability, low maintenance requirements, noise and vibration reduction, a wide range of vacuum levels, energy efficiency, versatility, and compatibility. These advantages make Roots vacuum pumps a preferred choice for many industrial processes that require efficient and reliable vacuum generation.

editor by Dream 2024-04-22

China Good quality Sk Air Circulation Liquid Ring High Vacuum Pump with High Capacity for Filtration/Package Machine vacuum pump engine

Product Description

Product Description

SK Series CHINAMFG Liquid(Water) Ring Vacuum Pump With CE Certificate

Overview

SK series liquid ring type vacuum pump is used to suction or compress air and other gas that is non-corrosive, unsolvable in water and with no CHINAMFG powder. so that vacuum and pressure can be obtained in the sealed container. However, the gas allow mix less amount of liquid.

The pump is widely used in mechanical, petroleum, chemical, pharmaceutical, food, ceramics, printing, metallurgy and other ways.

During it is operating, the air compression is constant temperature, it won’t easily result in any danger, when the pump is suctioning or compressing any flammable or explosive gas. Therefore, the pump is widely used.

Applications

They are mainly for pumping air and other gases which have certain corrosively and a small amount of dust, and are not soluble in water, and widely used in the technical processes of vacuum evaporation, concentration, feeding, dehydration, drying, and so on in food, textile, medicine, chemical industry and other fields.Pumps of this series possess compact structures, and are reliable to use, convenient to install and disassemble, and easy to maintain.

Product Parameters

|

Model |

(m3/min) |

(Pa) |

(Kw) |

(rpm) |

(L/min) |

(mm) |

(kg) |

|

SK-1.5 |

1.5 |

6.7×103 |

4 |

1440 |

10~15 |

Φ65 |

180 |

|

SK-3 |

3 |

6.7×103 |

7.5 |

1440 |

15~20 |

Φ65 |

275 |

|

SK-6 |

6 |

6.7×103 |

15 |

1460 |

25~35 |

Φ100 |

450 |

|

SK-12 |

12 |

6.7×103 |

22 |

970 |

40~50 |

Φ125 |

900 |

|

SK-20 |

20 |

6.7×103 |

37 |

740 |

60~80 |

Φ150 |

1940 |

|

SK-30 |

30 |

6.7×103 |

55 |

740 |

70~90 |

Φ150 |

2340 |

Note : There is more models for bigger flow rate and higher lift , but it can not be listed all.

Please contact us to ask for more models !!!

Detailed Photos

Packaging & Shipping

Packing Details : One pump in One plywood case

Delivery Details : 30 days after order confirmation

Standard package without original wood, no fumigation needed.

Company Profile

ZheZheJiang oto Pump Industrial Co., Ltd. is a professional pump manufacturer integrating R&D, manufacturing, sales and service as a whole, which has been certified by ISO9001 international quality management system.

Located in Xihu (West Lake) Dis.a Industrial Park, ZheJiang , CHINAMFG Pump Industrial possesses 2 manufacturing bases in ZheJiang and ZHangZhoug. Since our inception, CHINAMFG Pump Industrial has been committed to the innovation and development of various pumps. Our leading products include self-priming trash pump, centrifugal pump, submersible pump, diaphragm pump, vacuum pump, diesel pump, fire pump, etc.

FAQ

Q: Can I chat with you online? What is your company official website?

A: Yes.

Q: What type of company CHINAMFG is?

A: CHINAMFG is a manufacture and trading company, has factories in ZheJiang and ZHangZhoug, with export and import license.

Q: What kinds of pumps do you supply?

A: Our products including self-priming trash pump, centrifugal pump, diaphragm pump, submersible pump, chemical pump, oil pump, diesel pump, fire fighting pump, etc.

Q: What is your payment terms?

A: Alibaba Trade Assurance, Western Union, Paypal, T/T, L/C, etc.

Q: Can you provide OEM, ODM service?

A: Yes. We have factories in ZheJiang and ZHangZhoug, we can make products according to your requirements.

Q: Why should we buy from you?

A: We are committed to provide best quality products at minimum delivery time and competitive price. We believe this is what customer wants. We are satified until customers are.

Q: What is your warranty period?

A: We provide 1 year of unconditional warranty on our products for the manufacturing defects.

Q: What about delivery time?

A: Normally our production time is within 2 weeks. Please confirm before order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Oil or Not: | Oil Free |

| Structure: | Jet Flow Vacuum Pump |

| Exhauster Method: | Positive Displacement Pump |

| Vacuum Degree: | Low Vacuum |

| Samples: |

US$ 1300/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How Are Vacuum Pumps Employed in the Production of Electronic Components?

Vacuum pumps play a crucial role in the production of electronic components. Here’s a detailed explanation:

The production of electronic components often requires controlled environments with low or no atmospheric pressure. Vacuum pumps are employed in various stages of the production process to create and maintain these vacuum conditions. Here are some key ways in which vacuum pumps are used in the production of electronic components:

1. Deposition Processes: Vacuum pumps are extensively used in deposition processes, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), which are commonly employed for thin film deposition on electronic components. These processes involve the deposition of materials onto substrates in a vacuum chamber. Vacuum pumps help create and maintain the necessary vacuum conditions required for precise and controlled deposition of the thin films.

2. Etching and Cleaning: Etching and cleaning processes are essential in the fabrication of electronic components. Vacuum pumps are used to create a vacuum environment in etching and cleaning chambers, where reactive gases or plasmas are employed to remove unwanted materials or residues from the surfaces of the components. The vacuum pumps help evacuate the chamber and ensure the efficient removal of byproducts and waste gases.